Colorado1135

Well-known member

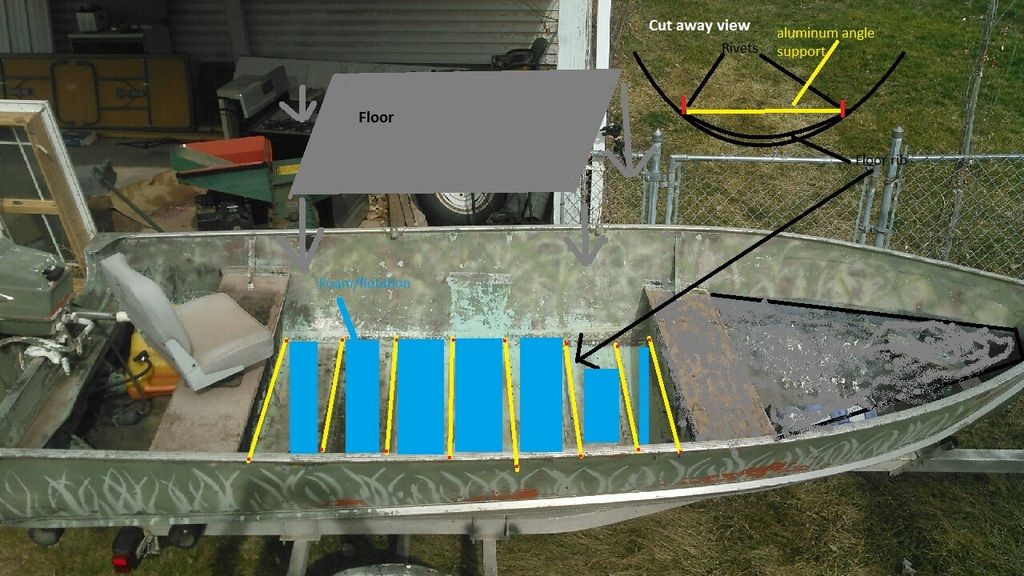

Been around boats most of my life, used many kinds but now that I own my own one I find myself stumped with simple questions that most boat owners do or should know. I decided to do it right and buy a fixer upper and learn every square inch of her as I go. might be a hard lesson, but I will know every rivet and rib before I'm done. so before I get long winded I'll post a pic of my gem and what I have done so far (hopefully correctly).

This is the day I brought her home

So far I have stripped the painted sides, applied etching primer and painted it with implement paint. I figure Grey would be a good comfortable color reminding me of my Navy days.

I'm about to start on the deck and I realized I have no idea where to start. I tried searches on basic info but to no avail. the questions I have are:

What are the Do's and Don'ts to a project like this?

Are pop rivets ok to use, and where?

how do I select my floor supports, and how do they tie in to the hull?

is it taboo to put holes in the hull? I would think so..

is there a way to rivet the same way Lund did when she was built?

where do I find seats? can I make my own?

Should I strip and paint the inside, or leave it since it will be covered up?

what's the best way to test the rivets? fill it with water? or will a suction cup work?

I feel like a total novice and don't know where to start. I figured I would ask now than come later and say "hey I did this, how do I fix my screw up?"

pictures do wonders, especially close ups.

can anybody steer me in the right direction?

Thank you in advance!

Ryan

This is the day I brought her home

So far I have stripped the painted sides, applied etching primer and painted it with implement paint. I figure Grey would be a good comfortable color reminding me of my Navy days.

I'm about to start on the deck and I realized I have no idea where to start. I tried searches on basic info but to no avail. the questions I have are:

What are the Do's and Don'ts to a project like this?

Are pop rivets ok to use, and where?

how do I select my floor supports, and how do they tie in to the hull?

is it taboo to put holes in the hull? I would think so..

is there a way to rivet the same way Lund did when she was built?

where do I find seats? can I make my own?

Should I strip and paint the inside, or leave it since it will be covered up?

what's the best way to test the rivets? fill it with water? or will a suction cup work?

I feel like a total novice and don't know where to start. I figured I would ask now than come later and say "hey I did this, how do I fix my screw up?"

pictures do wonders, especially close ups.

can anybody steer me in the right direction?

Thank you in advance!

Ryan