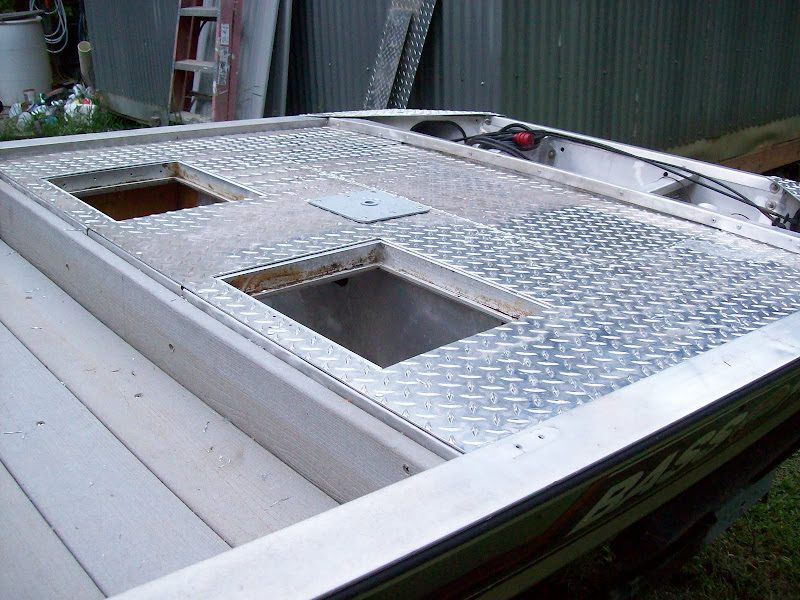

Just started to rip apart my tracker for a complete interior rebuild and possible paint. This boat was on the water this past year, but kept taking on water etc. I fixed a number of loose rivets, but still water everytime. So I made the decision to rip it apart this winter and rebuild it how I want it. I have gotten a lot of good advice from this forum and looking for some more help as I make my way through. As many of the people on the forum suggested, they thought I would find my floatation foam to be completely soaked. Well, it was soaked and saturated beyond what I would have ever thought. Tracker did some things whe they made these boats that just make no sense to me. All of the foam sandwiched between the floor and the hull was soaked, it was installed and just sitting in the water channels that run to the bilge?????? Stupid? Even the floor drain had foam installed directly below it, makes no sense. I have ripped out all the foam and plan to replace. Upon ripping apart the riveted jigsaw puzzle that is the back casting platform, I found more saturated foam and some construction that just seems cheap and stupid. Ahhh well the project should be fun and i look forward to setting it up how I want it and making it right.

My main questions right know are this:

1. The back casting platfom sides was built by just shooting foam into an aluminum case. there is no actual framing, just aluminum rails laid on top of the foam and then the aluminum case was rivited to the rails????? Do you think I should frame something out here or just repour the foam, once I remove the exsiting? Also where thes foam blocks are located, could I just frame this out and make dry storage on both sides? Or so you think this foam is crucial?

2. When replacing the floor foam, what should I use or how would I keep the foam from getting saturated as there is no real way I can think of to keep the foam raised above the floor to fkeep it away from any water?

3. Gluvit or what product should I use to ensure no water entry? I want to coat the hull with something to make this boat dry. I want a dry boat that is my number one goal.

More questions later, thanks for your help.....this is a much bigger project than I anticipated when i boaught this boat!!!! But again having fun doing it.

My main questions right know are this:

1. The back casting platfom sides was built by just shooting foam into an aluminum case. there is no actual framing, just aluminum rails laid on top of the foam and then the aluminum case was rivited to the rails????? Do you think I should frame something out here or just repour the foam, once I remove the exsiting? Also where thes foam blocks are located, could I just frame this out and make dry storage on both sides? Or so you think this foam is crucial?

2. When replacing the floor foam, what should I use or how would I keep the foam from getting saturated as there is no real way I can think of to keep the foam raised above the floor to fkeep it away from any water?

3. Gluvit or what product should I use to ensure no water entry? I want to coat the hull with something to make this boat dry. I want a dry boat that is my number one goal.

More questions later, thanks for your help.....this is a much bigger project than I anticipated when i boaught this boat!!!! But again having fun doing it.