First off this is an awesome site. Tons of awesome ideas and a bunch of people willing to give advice.

Was finally able to find a decent deal on a 16 footer over the weekend so I pulled the trigger and brought her home. I recently moved to a subdivision that has river access with a boat ramp about 300 yards from my front door. I sold my old 12 footer before we moved, so a new (to me) boat was in the near future. Got myself a '95 Tracker Sportsman 1648 with a like new '06 Valu-Line trailer. Couldn't be more excited!! Going to be a long and expensive project, but I hope to have her finished by the spring, which helps give me time to gather funds as the project progresses. Will be used for fishing (mostly catfish with occasional musky and smallmouth chasing) and duck/goose hunting the potomac river. I'm hoping to make this boat last a LONG time, so I plan to try and do things right from the start. My plans include:

-Steelflex for the bottom of the hull and fresh paint everywhere else.

-Small aluminum bow deck, riveted to and braced with aluminum angle from the existing bow deck back to the first rib in front of the middle bench.

-Dry storage and storage for batteries under deck.

-Removal of the middle bench seat for a more open floor.

-Aluminum sheet for flooring. (Foam beneath)

-Aluminum sheet to cover gunwalls similar to what caveman and dixie_boysles did in their builds. https://www.tinboats.net/forum/viewtopic.php?f=21&t=7695&hilit=just+thinking

https://www.tinboats.net/forum/viewtopic.php?f=21&t=12178&start=105

-Hydroturf for the deck/floor/back bench.

-Hydroturf (or possibly something like grizzly grip) for the aluminum sheet up the gunnels.

-Transom replacement. Transom isn't in horrible shape, but I'd rather knock this out now than have to fool with it down the road.

-3 pin mounted seats. 1 captains seat, 1 in middle of open floor and 1 on the deck.

-Radio

-LED lighting mounted to the aluminum sheet on the gunwalls for night fishing.

-Hard wired nav/anchor lights

-Switch panel and 12V socket for spotlight

-Rod holders

-Fish finder/sonar

-25hp tiller and either bow or transom mounted trolling motor.

A few questions.

-What is the best way to reinforce the gunwalls after removing the middle bench? Is the decking/flooring and aluminum sheet up the gunwalls enough? I plan to bring the deck back to the first rib that's right in front of the existing bench, and floor the rest of the way back to the back bench with aluminum sheet attached to the ribs with stainless steel screws. I'll also be attaching the aluminum sheet on the gunwall to the ribs with stainless stell screws.

-When installing a pin mounted seat to an aluminum deck what do you attach it to? I'm thinking you would pattern your aluminum angle bracing so that the seat base is screwed through the aluminum sheet and the aluminum angle? How about attaching a pin mounted seat to an aluminum sheet floor?

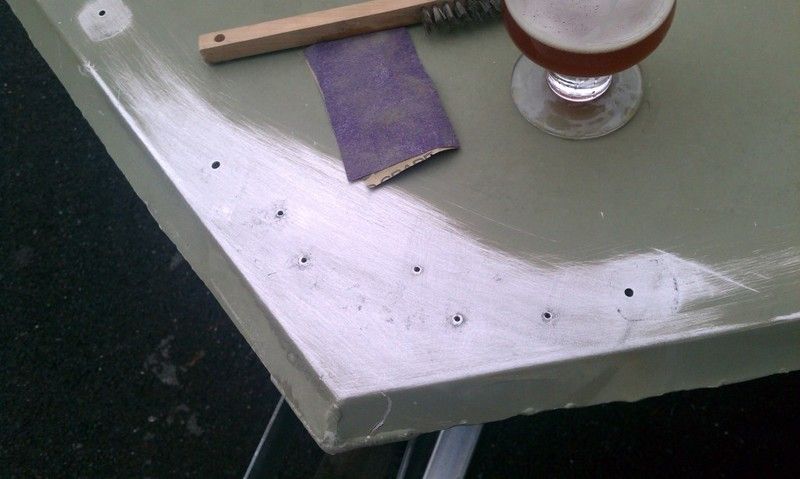

-The boats in good shape, but has some typical dents from running a rocky river. Whats the best way to deal with these? Leave them as is, or go to town with a rubber mallet?

I'm sure I'll have many questions along the way, and I already appreciate the help/advice I've gotten so far.

On to the pictures.

Was finally able to find a decent deal on a 16 footer over the weekend so I pulled the trigger and brought her home. I recently moved to a subdivision that has river access with a boat ramp about 300 yards from my front door. I sold my old 12 footer before we moved, so a new (to me) boat was in the near future. Got myself a '95 Tracker Sportsman 1648 with a like new '06 Valu-Line trailer. Couldn't be more excited!! Going to be a long and expensive project, but I hope to have her finished by the spring, which helps give me time to gather funds as the project progresses. Will be used for fishing (mostly catfish with occasional musky and smallmouth chasing) and duck/goose hunting the potomac river. I'm hoping to make this boat last a LONG time, so I plan to try and do things right from the start. My plans include:

-Steelflex for the bottom of the hull and fresh paint everywhere else.

-Small aluminum bow deck, riveted to and braced with aluminum angle from the existing bow deck back to the first rib in front of the middle bench.

-Dry storage and storage for batteries under deck.

-Removal of the middle bench seat for a more open floor.

-Aluminum sheet for flooring. (Foam beneath)

-Aluminum sheet to cover gunwalls similar to what caveman and dixie_boysles did in their builds. https://www.tinboats.net/forum/viewtopic.php?f=21&t=7695&hilit=just+thinking

https://www.tinboats.net/forum/viewtopic.php?f=21&t=12178&start=105

-Hydroturf for the deck/floor/back bench.

-Hydroturf (or possibly something like grizzly grip) for the aluminum sheet up the gunnels.

-Transom replacement. Transom isn't in horrible shape, but I'd rather knock this out now than have to fool with it down the road.

-3 pin mounted seats. 1 captains seat, 1 in middle of open floor and 1 on the deck.

-Radio

-LED lighting mounted to the aluminum sheet on the gunwalls for night fishing.

-Hard wired nav/anchor lights

-Switch panel and 12V socket for spotlight

-Rod holders

-Fish finder/sonar

-25hp tiller and either bow or transom mounted trolling motor.

A few questions.

-What is the best way to reinforce the gunwalls after removing the middle bench? Is the decking/flooring and aluminum sheet up the gunwalls enough? I plan to bring the deck back to the first rib that's right in front of the existing bench, and floor the rest of the way back to the back bench with aluminum sheet attached to the ribs with stainless steel screws. I'll also be attaching the aluminum sheet on the gunwall to the ribs with stainless stell screws.

-When installing a pin mounted seat to an aluminum deck what do you attach it to? I'm thinking you would pattern your aluminum angle bracing so that the seat base is screwed through the aluminum sheet and the aluminum angle? How about attaching a pin mounted seat to an aluminum sheet floor?

-The boats in good shape, but has some typical dents from running a rocky river. Whats the best way to deal with these? Leave them as is, or go to town with a rubber mallet?

I'm sure I'll have many questions along the way, and I already appreciate the help/advice I've gotten so far.

On to the pictures.