DownSouthGaBoy

Active member

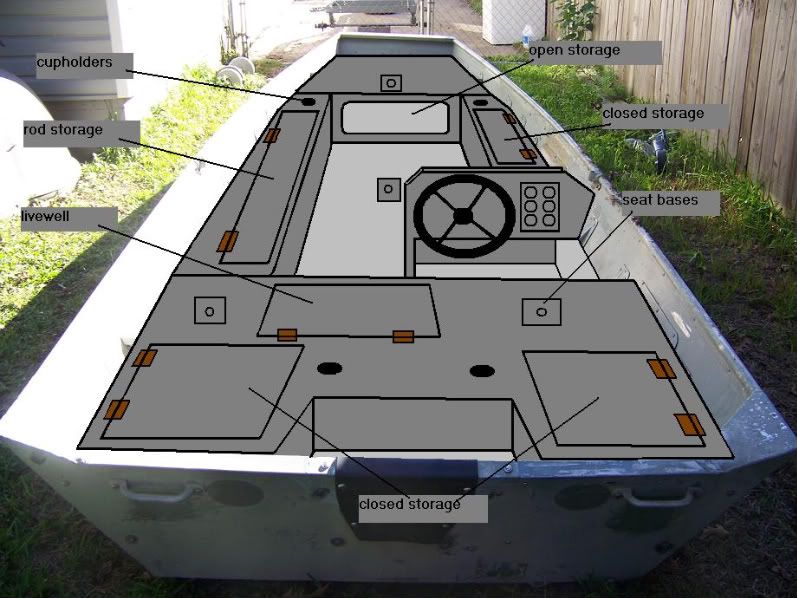

This is my first tinboat. Hoping to do well with it. Got it for $250 with the trailer and a whole pile of stuff for it. One of the previous owners had tried to construct storage along the sides and put a floor in it but half assed the construction. Fortunately though he used aluminum sheets and angle to build them, so i have a bunch of aluminum to use in my remodel. Also came with steering console and controls, anchor, and aerators. Never took pics before I started but figured I would get some before I got too far in, so here it is stripped of the floor, front deck and storage, back to basic. Also stripped the trailer painted it, replacing safety chains, trailer jack, bunks, lights, etc...