tripleup05

Well-known member

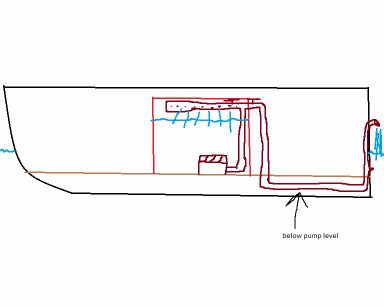

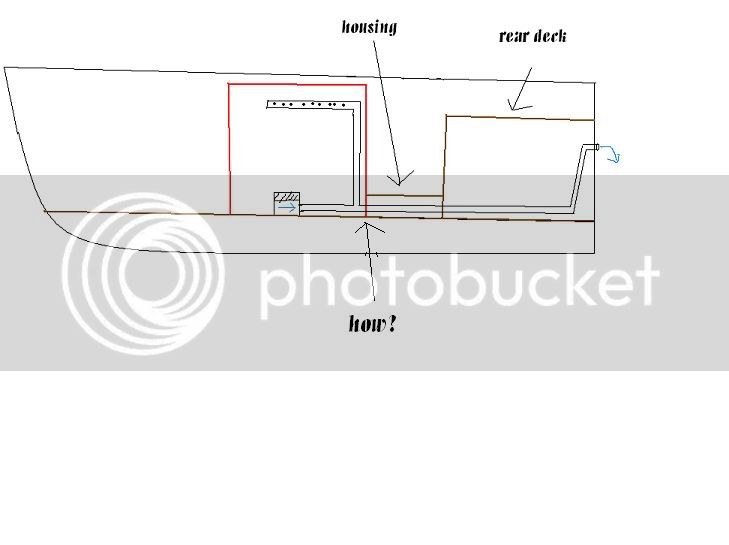

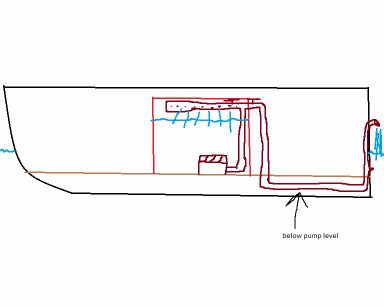

Hey guys. I am planning on doing my livewell similar to Perchin's. I like the idea of pumping the water out instead of depending on an overflow system. I have included a quick sketch of my design (sorry, i truly am terrible at Paint). The only problem is that I just found in my pump instructions not to have any point of the plumbing below the pump. From Attwood's website:

"HOSE CONNECTION INSTRUCTIONS

IMPORTANT: To prevent airlock, hose must rise continually upward

to the thru-hull connector with no dips or sharp bends. Support hose

if necessary."

https://www.attwoodmarine.com/userfiles/store/product/files/990/69390-a-tsunami-bilge-eng.pdf

Do you think that running the plumbing below the pump would be an issue, like the instructions say? I really would like everything to be below the floor, and then come back out of the floor right at the stern and run up it to a thru-hull.

"HOSE CONNECTION INSTRUCTIONS

IMPORTANT: To prevent airlock, hose must rise continually upward

to the thru-hull connector with no dips or sharp bends. Support hose

if necessary."

https://www.attwoodmarine.com/userfiles/store/product/files/990/69390-a-tsunami-bilge-eng.pdf

Do you think that running the plumbing below the pump would be an issue, like the instructions say? I really would like everything to be below the floor, and then come back out of the floor right at the stern and run up it to a thru-hull.