Aaron Lariscy

Well-known member

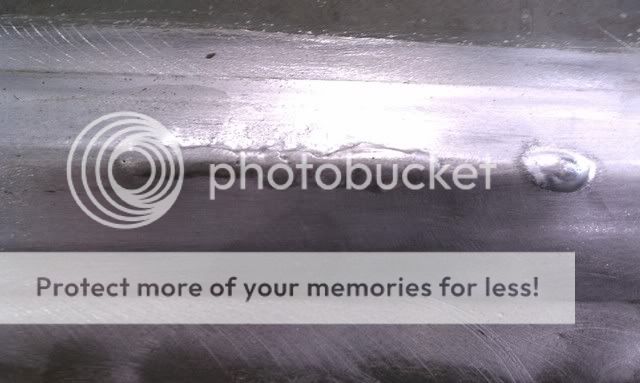

Are there any aluminum welders on here? I am pretty good at tigging nice clean new aluminum but I have one heck of a time doing repairs on a 20+ year old aluminum boat. Could anyone share some tips on how to clean an old boat up so you can make effective welds? The newest boat I need to repair has a crack right down the center of a rib on the bottom of the boat, kicker is that it is directly under the rear bench which I know is filled with foam. I can clean the outside pretty well but I am still going to suck trash from the inside that I can't clean.