Byrdmen

Active member

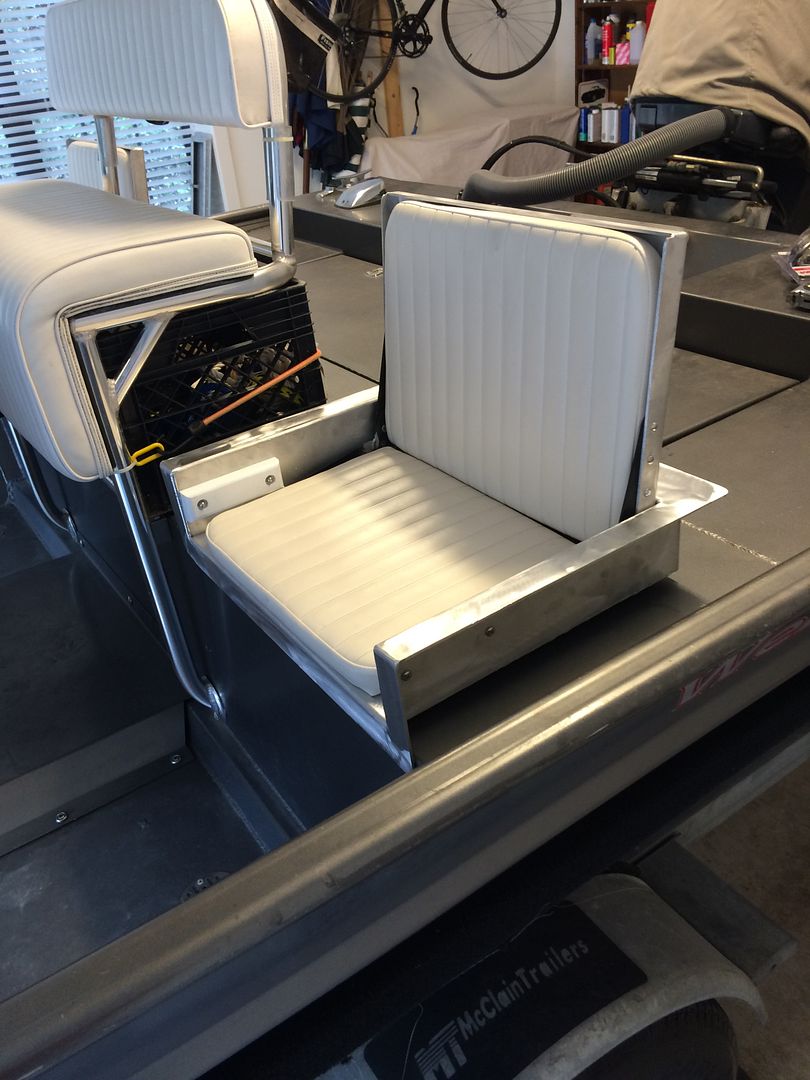

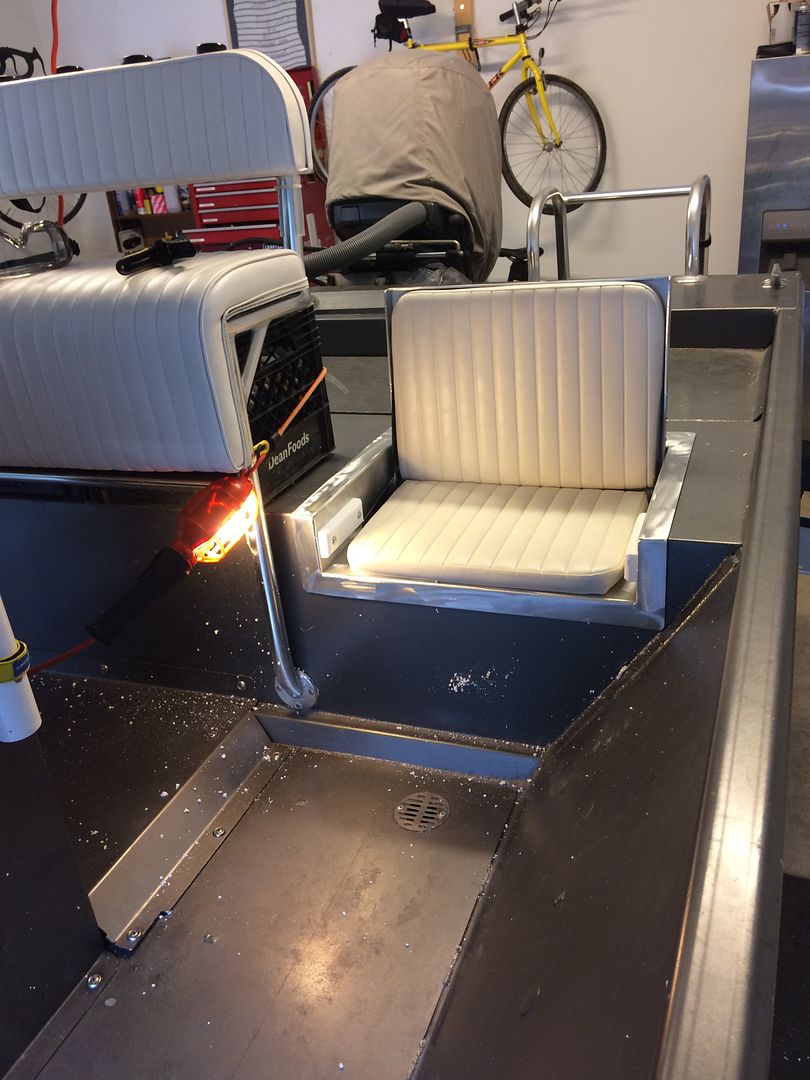

Owned a WeldCraft 1870 for a couple of years now, had Glen at Custom Marine Concepts here in Spring, TX do quite a bit of work including wading ladder, leaning post, and recently a back for the leaning post and grab rail.

Two problems have bothered me since I first got the boat, way too light up front and no good place up front for the trolling battery. A previous owner mounted the single trolling battery under the forward bench which did help add weight forward but the battery never really fit and the box came loose once in rough water on Lake Livingston. I also got tired of having to run to the back of the boat to get the anchor which almost never made it back there when I was done.

I kept looking at the forward area that is inaccessible as a possible location for the battery and possibly the anchor.

I looked the forward deck over and there are some braces that support the front deck from side to side with a clear 10" to be cut for the hatch.

I called R&R Designs in Terrell, TX (972) 524-1789, and ordered two custom sized aluminum hatches. The first was to fit the forward deck was ordered for a cut out of exactly 10" wide and 22" long to provide room to store the anchor. I ordered a second that fit an 8" by 20" cutout to close off the forward bench storage (haven't decided if I will install this one or not).

She charged me $40 and $50 for the hatches, tax, and about $15 for UPS ground shipping from Terrell. The hatches outside dimension adds 1.5" total to the cutout dimension, while the clear opening is 2.5" total less than the cutout dimension. So my forward hatch that was ordered for a cutout of 10"x22" has an outside dimension of 11.5"x23.5" and a clear opening of 7.5"x19.5".

Received the hatches about two weeks after I ordered them and they are a thing of beauty. She offered to paint them prior to shipping (powder coat?) but I could not describe my charcoal gray boat that nearly matches the Chrysler Dupli-Color paint I use to touch it up. They came in a clean natural aluminum finish that I could have left unpainted.

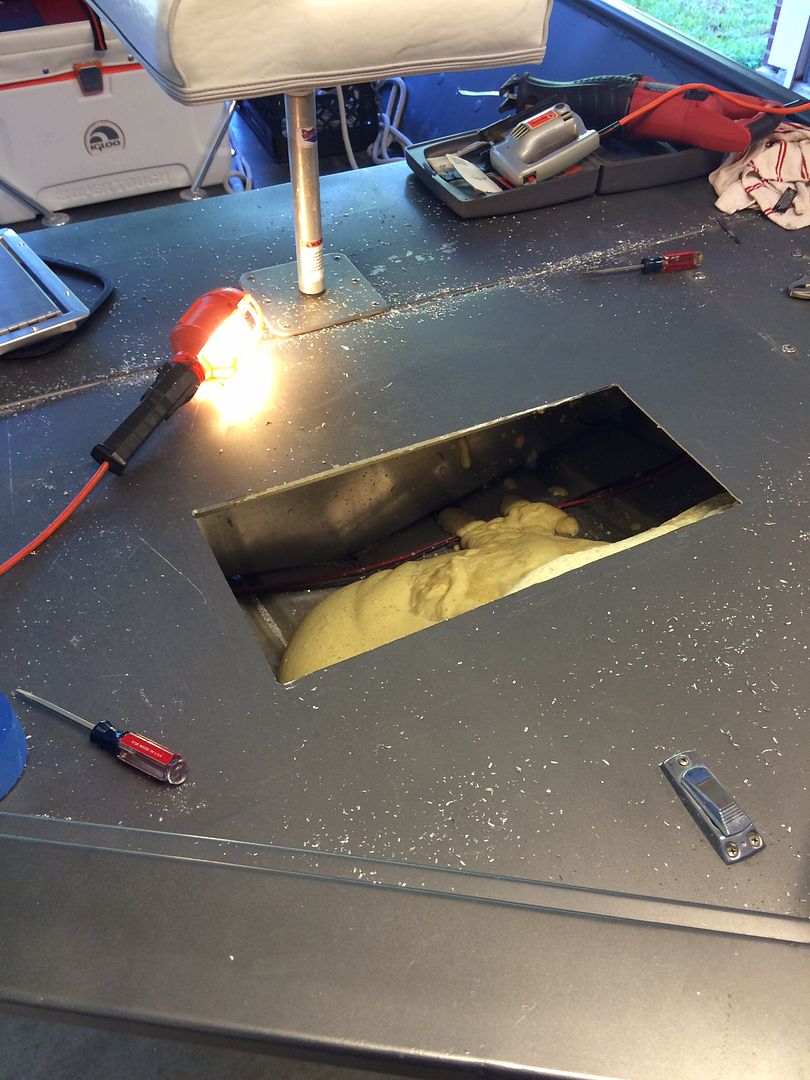

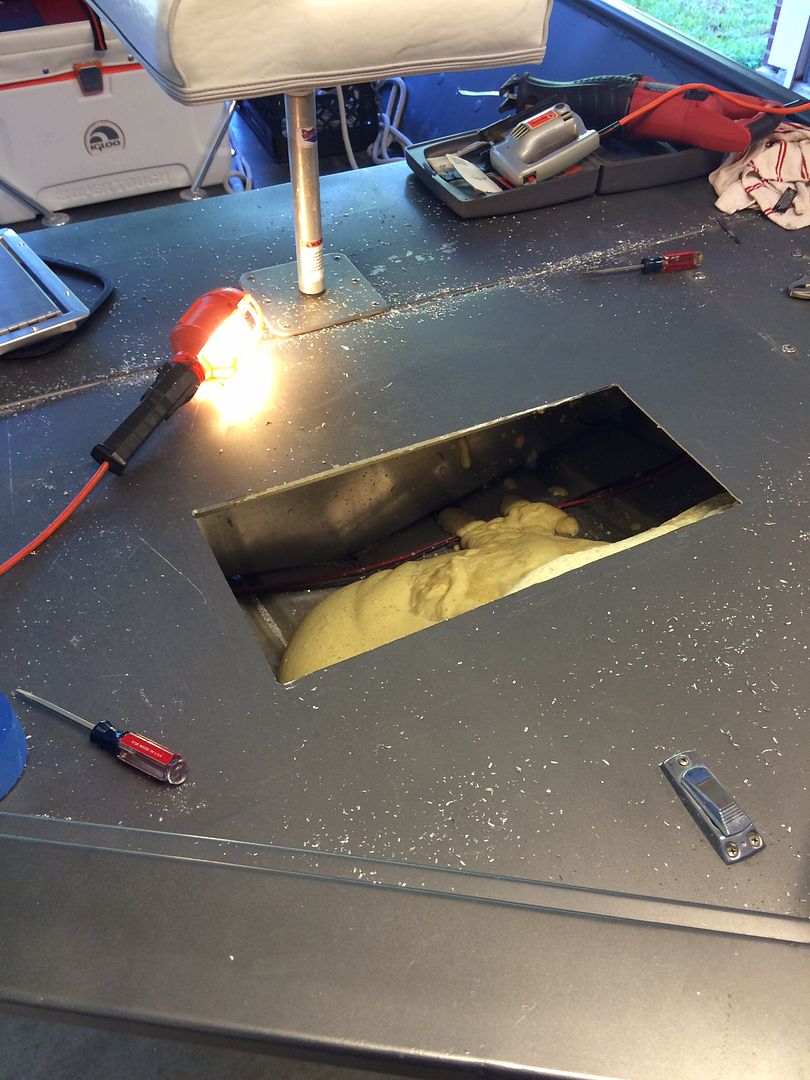

This morning I got busy cutting out the hole for the forward hatch. I started with the jigsaw and finally went with the circular saw. What ever you choose, eye and ear protection are a must!

Tried the recip saw, blade was too long and it didn't work at all. Wore out the shop vac keeping up with the aluminum chips.

Cleaned up the saw line with a sanding flap disk on my grinder, good thing as I kept hitting my hand and arms on the edge while removing expanding foam.

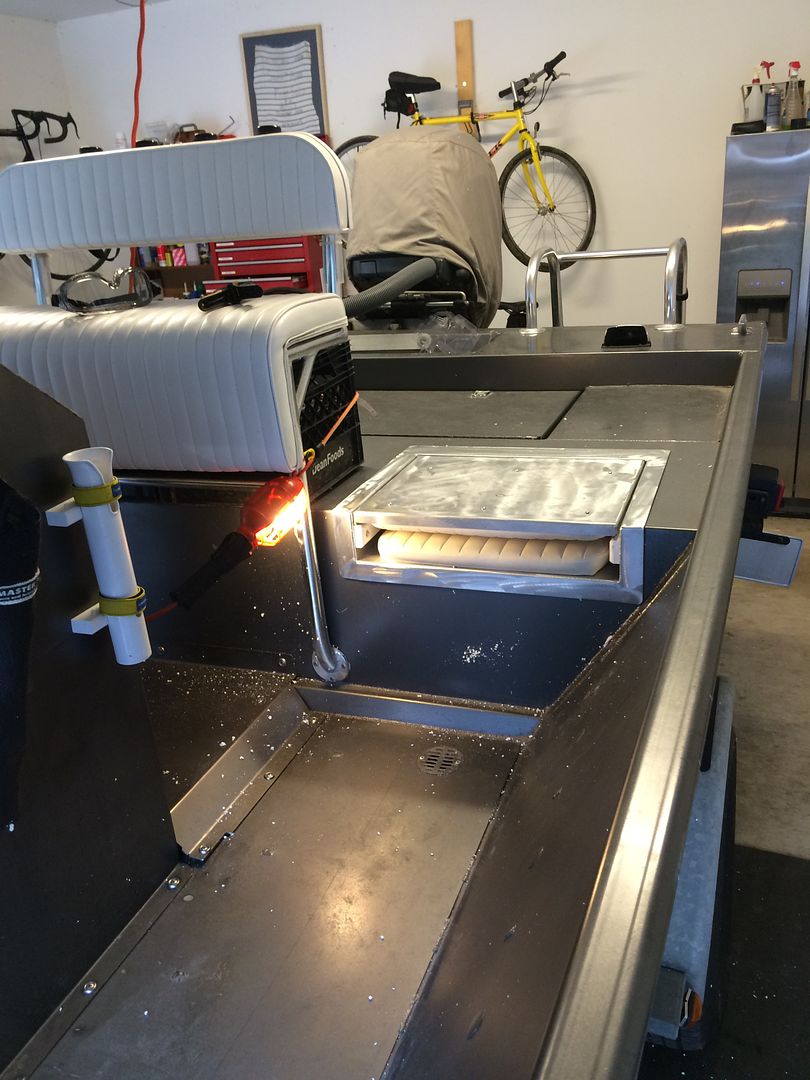

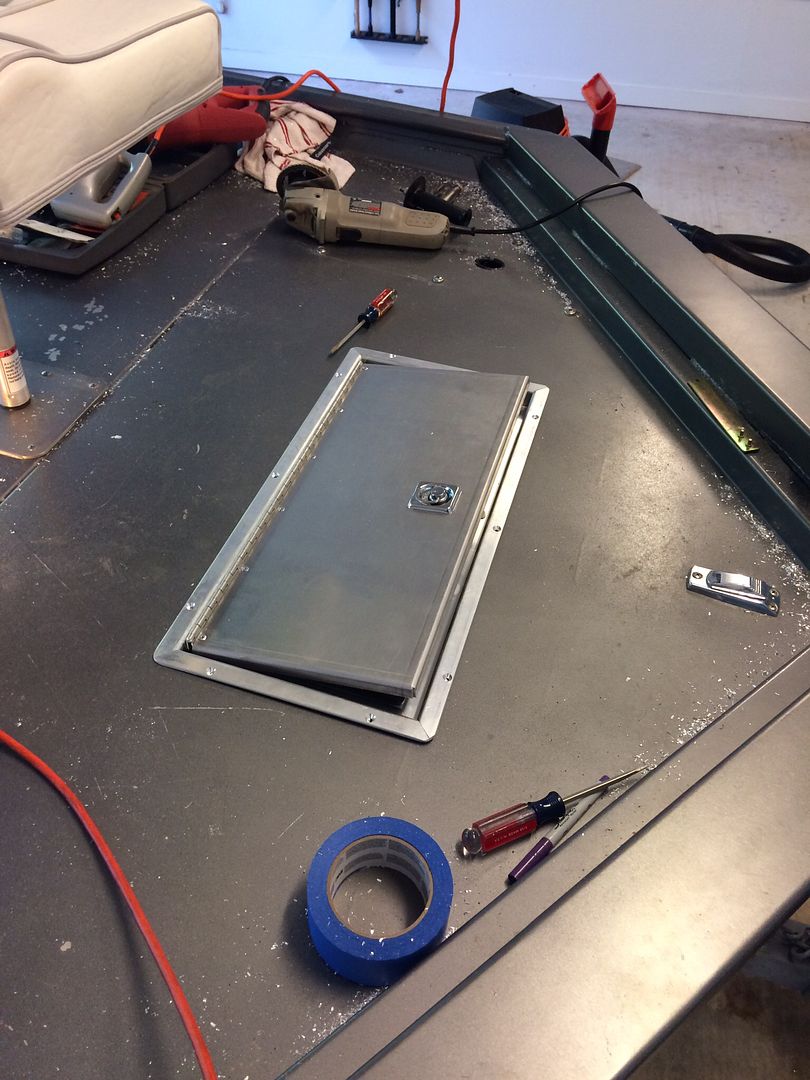

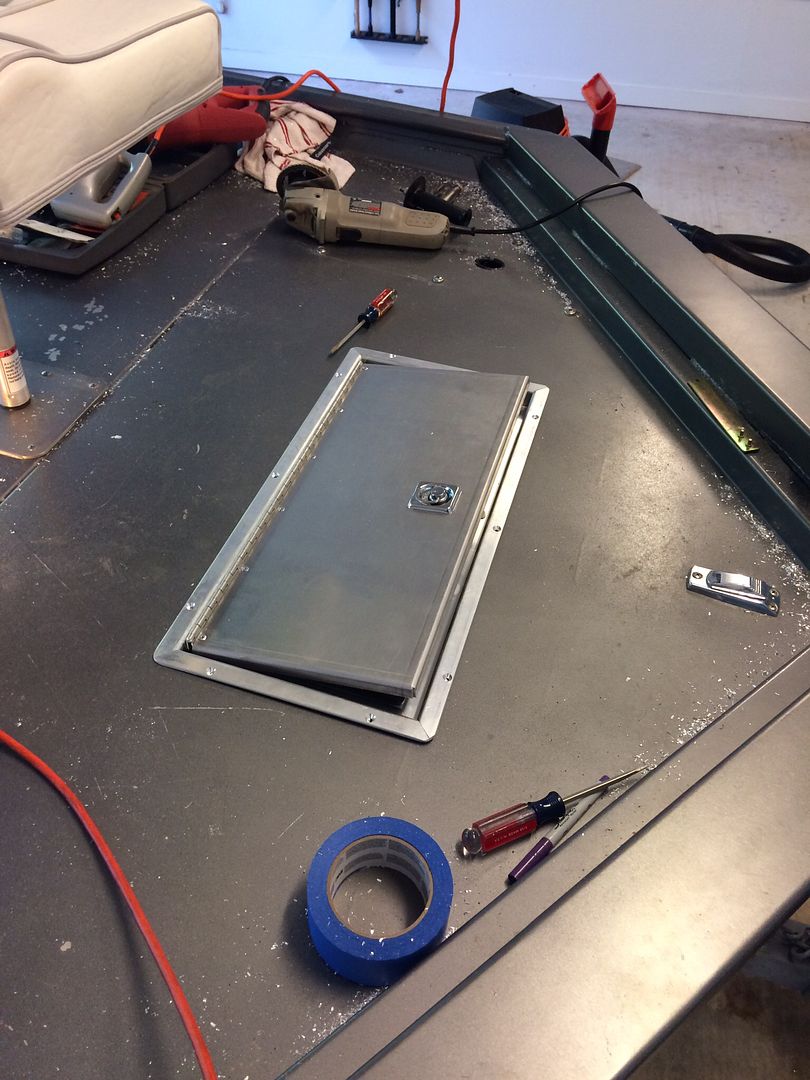

Test fit:

Once I knew it fit I pulled the latch off, cleaned, primed and painted with (nearly) matching paint.

I was planning to use aluminum rivets to hold the hatch in place, maybe with a little 4200. R&R predrilled and pre counter sunk for #10 screws in 10 evenly spaced locations around the frame but didn't quite drill out the bottoms of the holes, this allowed the 5/32" drill bit to self center on each of the 10 holes for a perfect flush fit (sure wasn't my skill!)

Still a little chicken to walk around on the boat barefoot, but in tennis shoes, very little lip from the fore deck to trip on and very little flex. The hatch door flexes about as much as the rest of the deck. I plan to take it out on Conroe this weekend if the weather allows to see if it rattles.

Still to do:

Two problems have bothered me since I first got the boat, way too light up front and no good place up front for the trolling battery. A previous owner mounted the single trolling battery under the forward bench which did help add weight forward but the battery never really fit and the box came loose once in rough water on Lake Livingston. I also got tired of having to run to the back of the boat to get the anchor which almost never made it back there when I was done.

I kept looking at the forward area that is inaccessible as a possible location for the battery and possibly the anchor.

I looked the forward deck over and there are some braces that support the front deck from side to side with a clear 10" to be cut for the hatch.

I called R&R Designs in Terrell, TX (972) 524-1789, and ordered two custom sized aluminum hatches. The first was to fit the forward deck was ordered for a cut out of exactly 10" wide and 22" long to provide room to store the anchor. I ordered a second that fit an 8" by 20" cutout to close off the forward bench storage (haven't decided if I will install this one or not).

She charged me $40 and $50 for the hatches, tax, and about $15 for UPS ground shipping from Terrell. The hatches outside dimension adds 1.5" total to the cutout dimension, while the clear opening is 2.5" total less than the cutout dimension. So my forward hatch that was ordered for a cutout of 10"x22" has an outside dimension of 11.5"x23.5" and a clear opening of 7.5"x19.5".

Received the hatches about two weeks after I ordered them and they are a thing of beauty. She offered to paint them prior to shipping (powder coat?) but I could not describe my charcoal gray boat that nearly matches the Chrysler Dupli-Color paint I use to touch it up. They came in a clean natural aluminum finish that I could have left unpainted.

This morning I got busy cutting out the hole for the forward hatch. I started with the jigsaw and finally went with the circular saw. What ever you choose, eye and ear protection are a must!

Tried the recip saw, blade was too long and it didn't work at all. Wore out the shop vac keeping up with the aluminum chips.

Cleaned up the saw line with a sanding flap disk on my grinder, good thing as I kept hitting my hand and arms on the edge while removing expanding foam.

Test fit:

Once I knew it fit I pulled the latch off, cleaned, primed and painted with (nearly) matching paint.

I was planning to use aluminum rivets to hold the hatch in place, maybe with a little 4200. R&R predrilled and pre counter sunk for #10 screws in 10 evenly spaced locations around the frame but didn't quite drill out the bottoms of the holes, this allowed the 5/32" drill bit to self center on each of the 10 holes for a perfect flush fit (sure wasn't my skill!)

Still a little chicken to walk around on the boat barefoot, but in tennis shoes, very little lip from the fore deck to trip on and very little flex. The hatch door flexes about as much as the rest of the deck. I plan to take it out on Conroe this weekend if the weather allows to see if it rattles.

Still to do:

- Need to decide if I will install the hatch on the storage area opening on the forward bench, sure reduces the access area making it hard to get at the life jackets.

- Order a third hatch and box to make a small water resistant glovebox in teh console, currently no place to store wallet, keys, phone, etc.

- Install and secure the trolling battery.

- Come up with some kind of mat to keep the anchor and rode from rattling while under way.