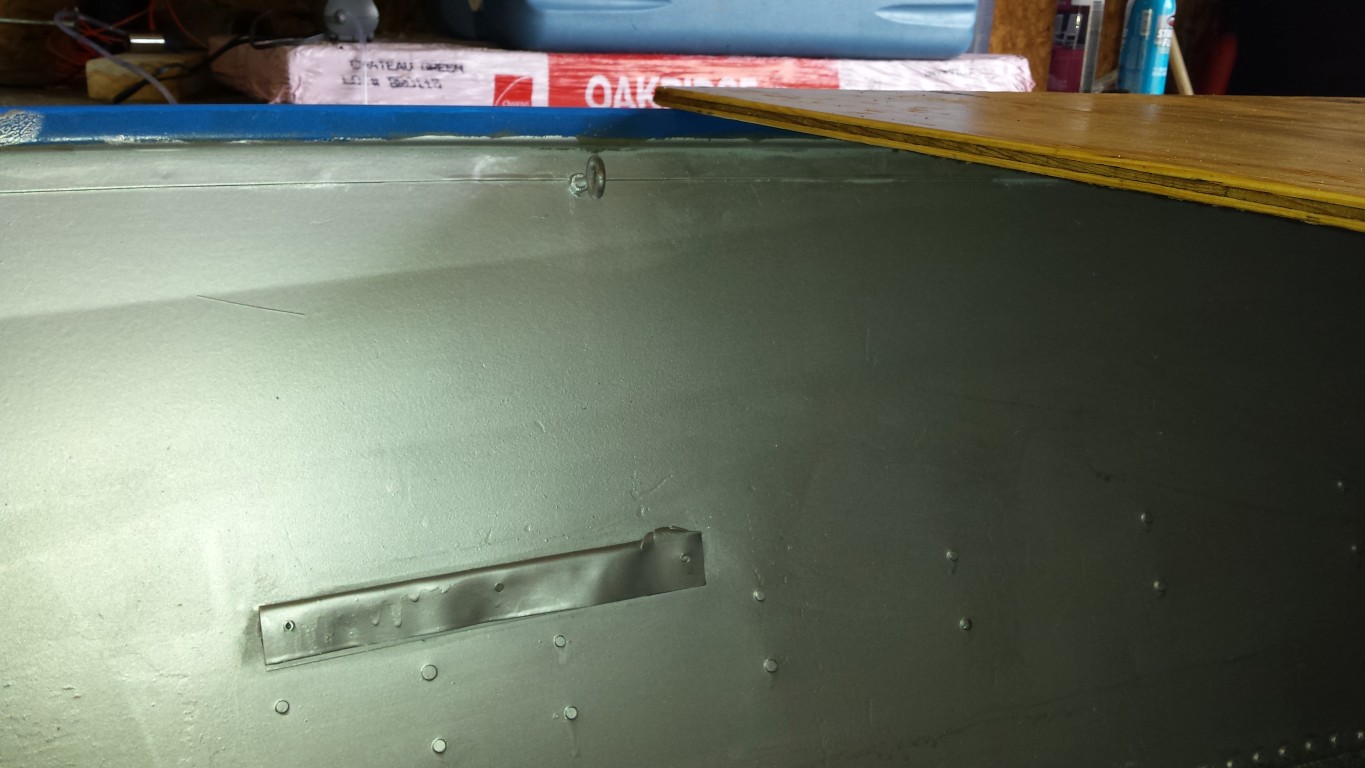

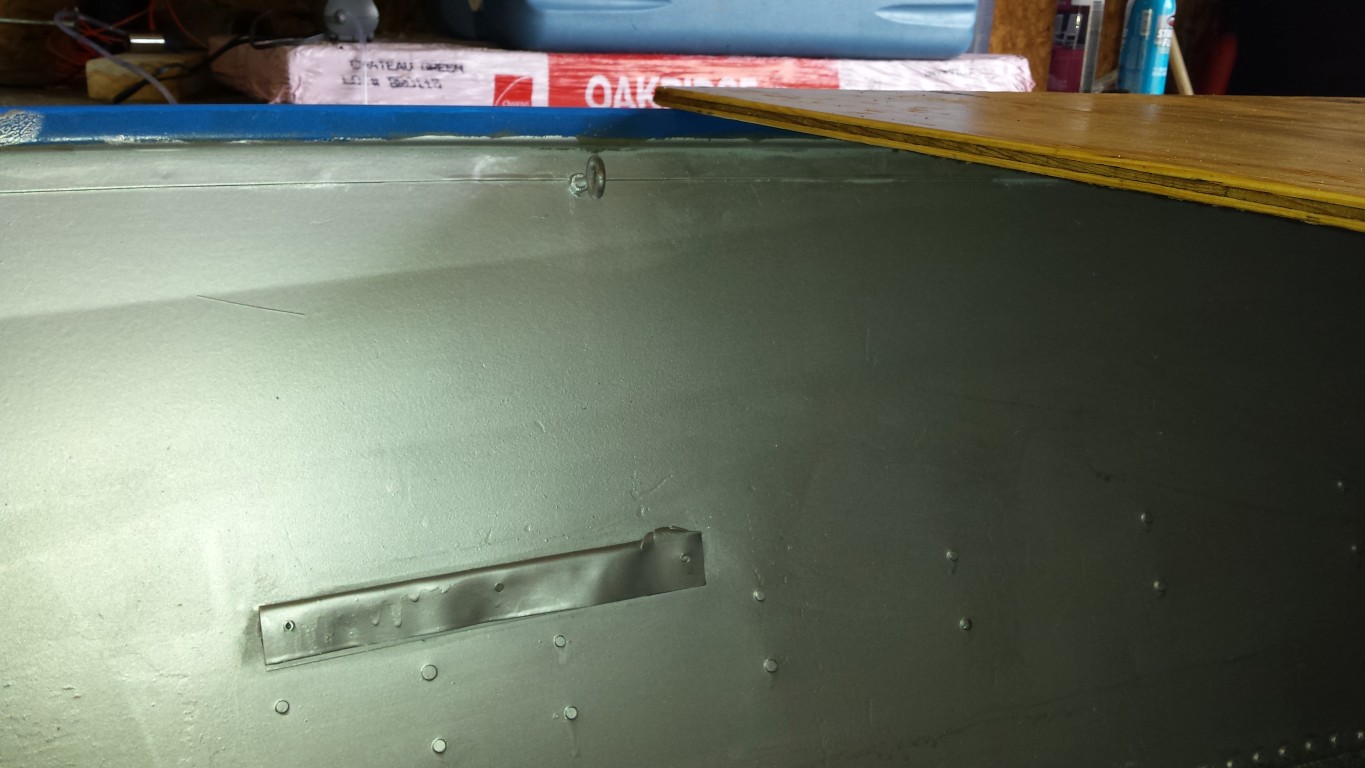

I cut a large sheet of plywood to go on the bow, to mount my trolling motor to, and underneath I'm gonna put elastic cargo net to hold life jackets.

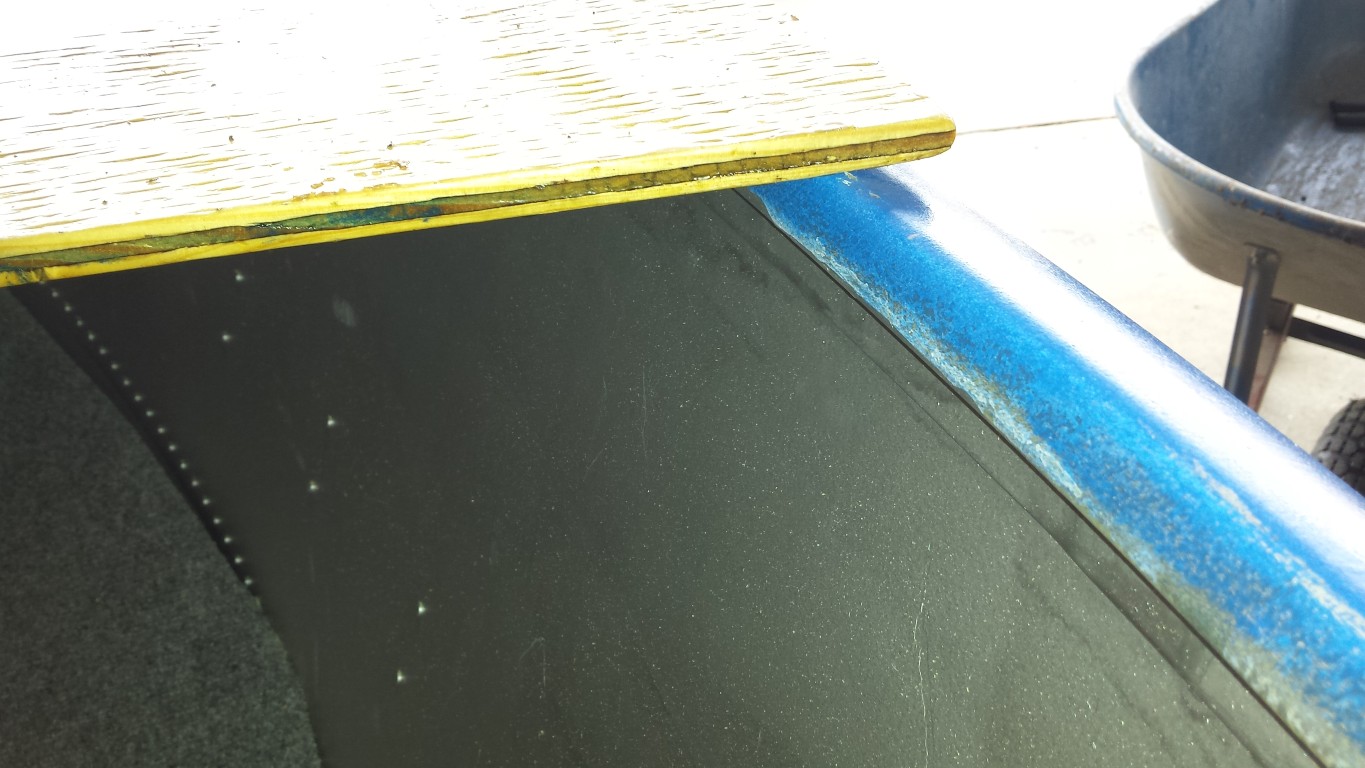

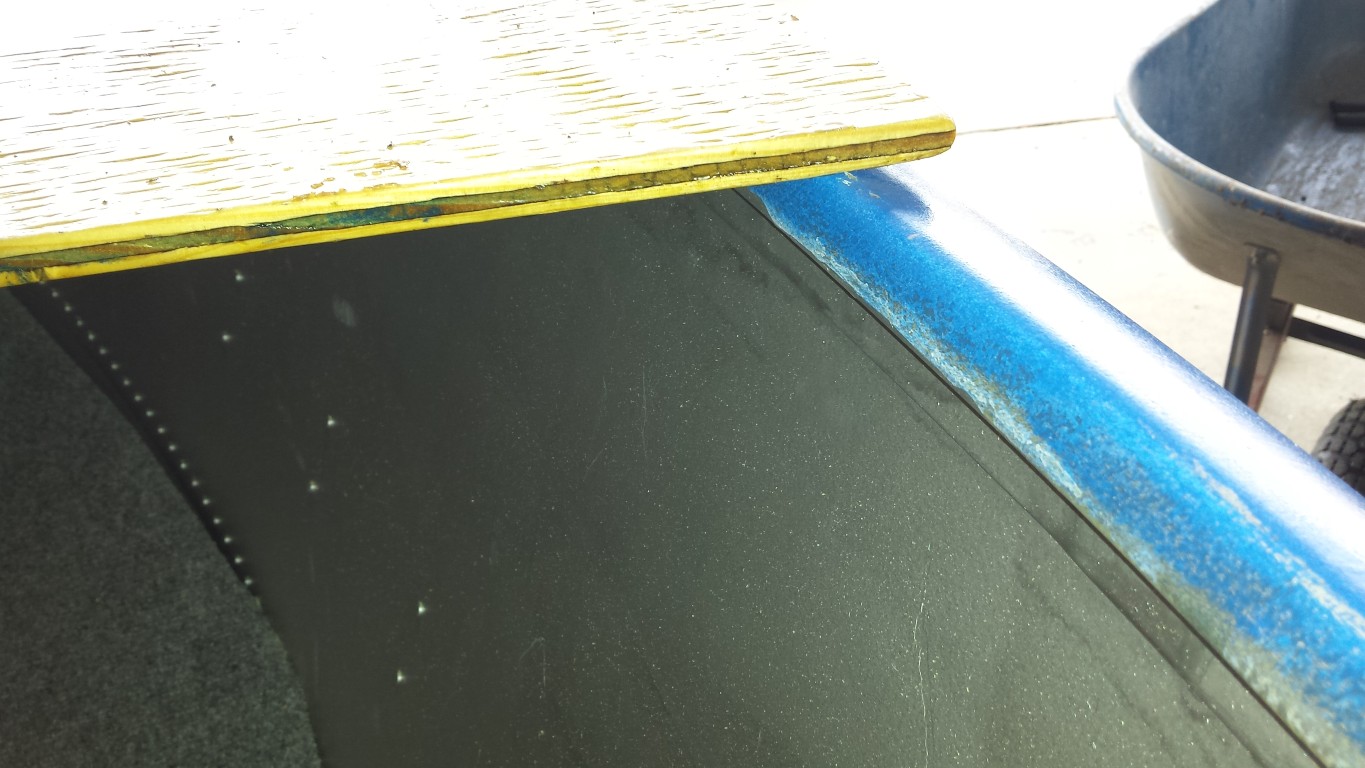

On the port side I ran 2 4-gauge wires to feed my trolling motor from the battery in the back, and on the starboard (OMG I feel so nautical!) I have the wires ran for the front marker and headlight. So....I can't really just drill through there.

There has to be some sort of thing I can put on the bottom of a bolt that'll grip the bottom of the gunwale and hold everything tight. But I walked around Menards the other day and couldn't find anything that would work.

Any ideas?

On the port side I ran 2 4-gauge wires to feed my trolling motor from the battery in the back, and on the starboard (OMG I feel so nautical!) I have the wires ran for the front marker and headlight. So....I can't really just drill through there.

There has to be some sort of thing I can put on the bottom of a bolt that'll grip the bottom of the gunwale and hold everything tight. But I walked around Menards the other day and couldn't find anything that would work.

Any ideas?