Macrosill

Well-known member

Go to 6:55 in this video

https://youtu.be/dXcqTxe4mzw?t=415

https://youtu.be/dXcqTxe4mzw?t=415

Gorilla Glue construction adhesive - comes in a caulk tube - works on foam boards. It also works on aluminum and almost anything else. This would be the correct adhesive for foam board. DAP also makes a foam board adhesive as well as Loctite PL.richg99 said:Pretty sure that the original Gorilla Glue will do the job. I'd call them first, though.

richg99 said:Pretty sure that the original Gorilla Glue will do the job. I'd call them first, though.richg99

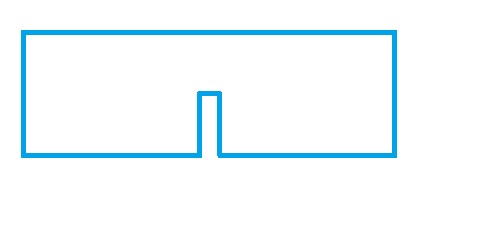

Shaugh said:no matter what kind of decking short of 3/4" you put on that edgewise foam you will be creating a lot of indentation wherever you're standing. That 200+ pounds will end up denting and degrading that thin foam edge very quickly. This type of egg carton frame works good on a waterbed for example where there is not a lot of direct pressure points but would not work well imo on a boat with thin decking above it.

Much better to spread that foot sized loading over a much larger surface like a block of foam ....

Enter your email address to join: