All,

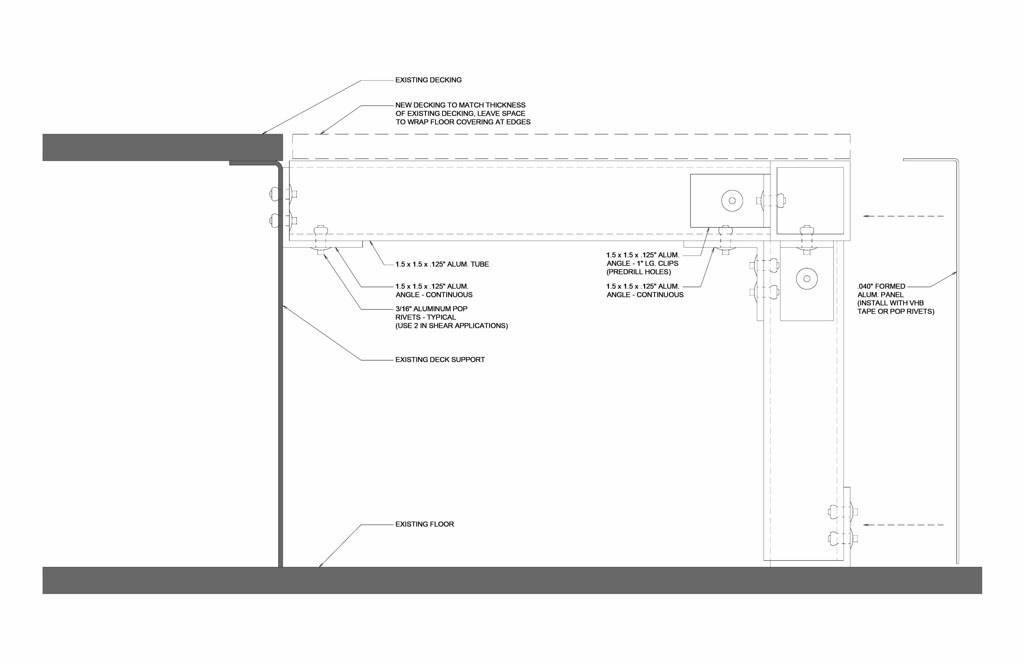

PolarKraft 15/44 installing deck for bass fishing. This boat, when I purchased for previous owner, had already been carpeted/floored. I want to extend front deck to console. Will be using 2 x 1/8 angle aluminum for deck structure.

I'm struggling how to connect the aluminum cross members to the sides AND how to mount vertical aluminum supports which will support the decking to the bottom of the boat. The sides/bottom are aluminum. See attached pictures

Thanks for any guidance.

terryd

PolarKraft 15/44 installing deck for bass fishing. This boat, when I purchased for previous owner, had already been carpeted/floored. I want to extend front deck to console. Will be using 2 x 1/8 angle aluminum for deck structure.

I'm struggling how to connect the aluminum cross members to the sides AND how to mount vertical aluminum supports which will support the decking to the bottom of the boat. The sides/bottom are aluminum. See attached pictures

Thanks for any guidance.

terryd