16Nymph

New member

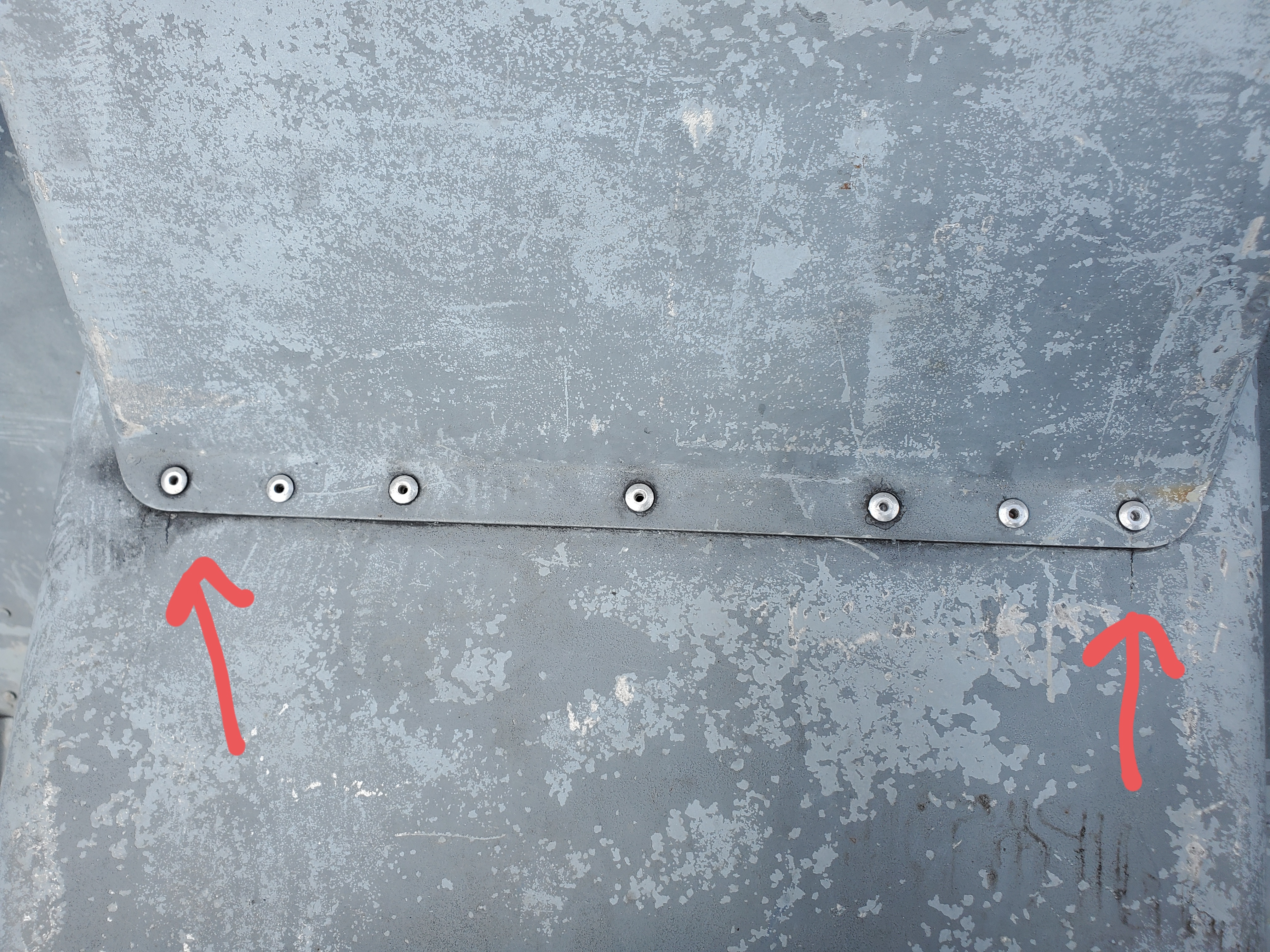

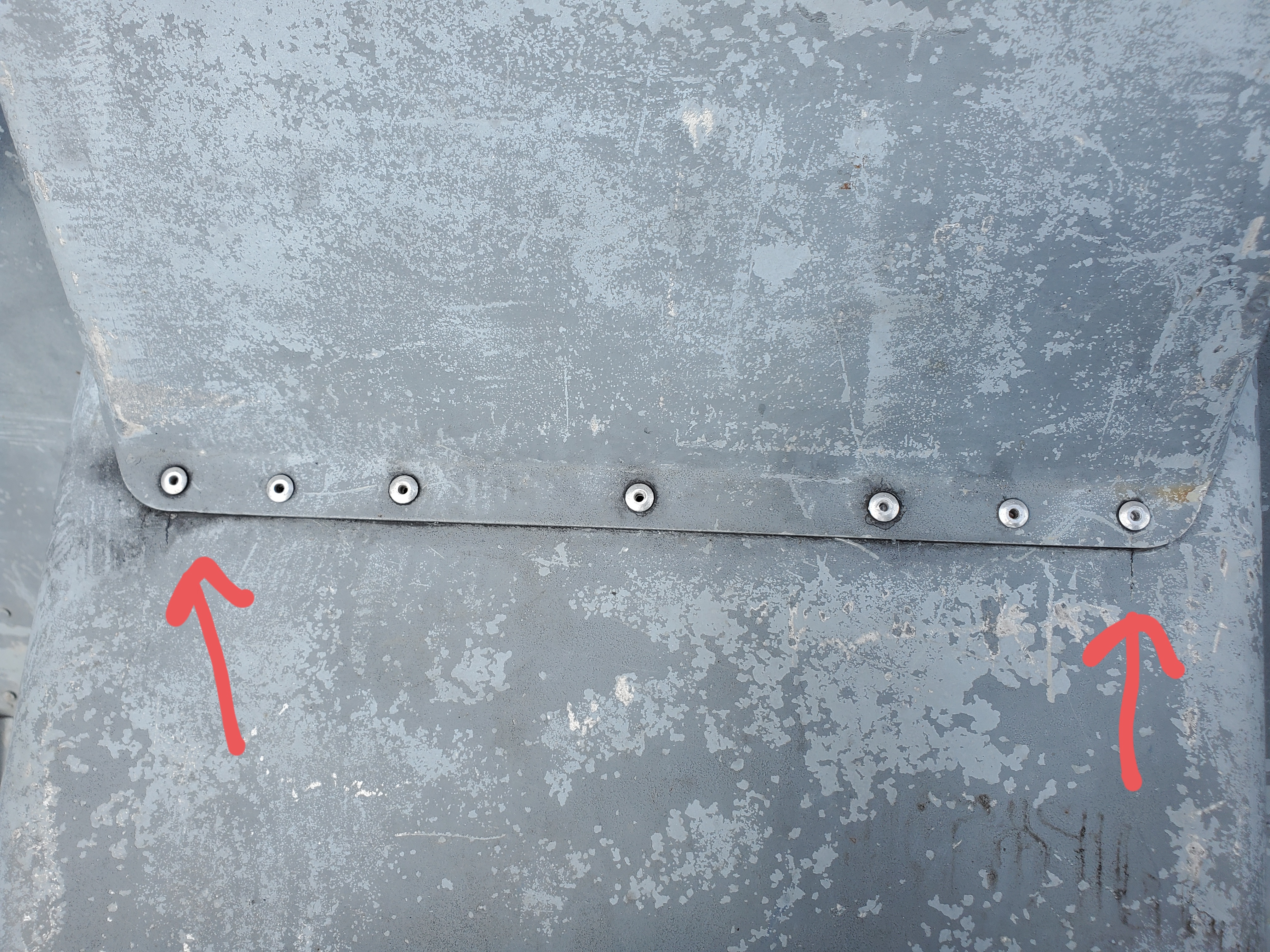

Picked up an early 90s Sea Nymph 16M which is a semi-V hull. Apparently has a bit thicker gauge aluminum than their other models. Anyway, I've been really pushing it to its limits in rough waters. Resultingly, its been flexing quite a bit and now the benches are cracking where they're riveted to the mounts at the hull. The cracks have gotten progressively worse and some rivets have broken off. It probably wouldn't happen if the support bracket extended the full width of the bench.

Any ideas on how one might repair this without somehow fabricating entirely new benches?

The best I could come up with is 'sandwiching' the width of the bench between 2 pieces of 1 or 2"wide aluminum flat bar and replacing rivets with bolts. Hopefully that'd stop it from getting worse and restore the structural support to some degree. I've put this off because the support bracket I'd need to remove for access uses solid rivets (not easily replaceable pop rivets) at the hull. I wonder if pop rivets would be ok to use here if I drill those solid rivets out.

I appreciate any feedback.

Any ideas on how one might repair this without somehow fabricating entirely new benches?

The best I could come up with is 'sandwiching' the width of the bench between 2 pieces of 1 or 2"wide aluminum flat bar and replacing rivets with bolts. Hopefully that'd stop it from getting worse and restore the structural support to some degree. I've put this off because the support bracket I'd need to remove for access uses solid rivets (not easily replaceable pop rivets) at the hull. I wonder if pop rivets would be ok to use here if I drill those solid rivets out.

I appreciate any feedback.