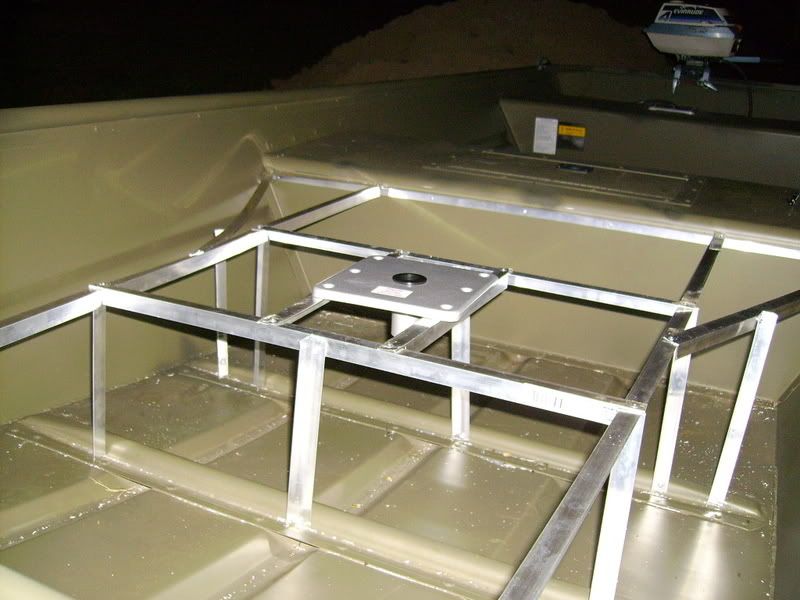

As I've looked through many of the pics of mods on aluminum angle framing, I have a hard time finding similar construction methods. Specifically, If it gets riveted or screwed, the number of rivets/screws per connection, the amount of support both horizontally and vertically etc.... I understand that it's ok for everyone to do it differently, because we all want different things out of our build, just wondering if any of you had to do it over again, knowing what you've seen and know now, would you do it any differently?

Also, I've seen some folks notch there angle to "fit" into another piece. It looks like this would weaken the connection. Are pop rivets an ok choice for load bearing applications? I'm realizing that I need to post a pic to help explain one of my questions. I will try to post it from another site.

Also, I've seen some folks notch there angle to "fit" into another piece. It looks like this would weaken the connection. Are pop rivets an ok choice for load bearing applications? I'm realizing that I need to post a pic to help explain one of my questions. I will try to post it from another site.