roblj65

Active member

Hi,

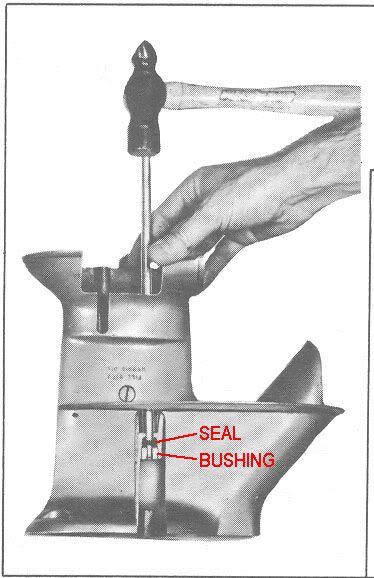

I'm fairly new to this Forum, as well as Outboard Repair. I bought a 1962 Starcraft a couple weeks ago, that has a 1966 18Hp Evinrude Fastwin on it. Boat had sat for 8 years prior to me getting it, and I did know enough that seals would have to be changed. Anyway, guy I bought it from had started it for me and it sounded pretty good, but once I got it home I checked Lower Unit Oil. Was None, so I filled it. Ran it for awhile in barrel and made sure water was circulating, and it was, but motor was sounding a little rough and it wouldn't shift into Forward, come to find out the forward gear and clutch were worn pretty bad, but I was able to get it redone at a machine shop, and it works well now. Also when I checked Lower Unit lube after running it, it was milky white. So I purchased a Sierra Seal kit that had absolutely no instructions with it, but the shop where I bought it said it's real easy to do(maybe if the drive-shaft O-ring weren't just about disintegrated and in the bottom of lower unit). So, I searched and searched and thought I figured out where everything went, but the O-ring that goes on the drive shaft I really wasn't sure about, and what I am assuming was the Drive-shaft O-ring that came with kit looked way to small, about a 1/4 inch in diameter,and not even a 16th of an inch thick, so I had some other Other O-rings kicking around and found one that looked about the size of the tiny piece that was left over from the disintegrated old one, and I placed it in the groove just below the spline of the top part of the drive-shaft. Also, the Spaghetti seal looked a little on the thin side, but what do I know? And the Drive-shaft seal and the Drive seal were only about half the thickness of the ones that were in there, don't know if that matters or not. Also did the water pump repair kit, minus the housing, as it didn't look that bad to me, and I just couldn't afford the $68.00 for a new one. So, after staying up all night doing this I put the finished motor back in the barrel, water seems to be circulating fine, but then I see oil quickly gathering in the barrel of water, so I shut the motor down, only to see the dreaded milky white oil-water mixture oozing from a hole on the back of the lower unit. I don't know what to do now, especially with no service manual, and I am out of money now. Is it salvageable without having to dump more money on another seal kit? Really would like to get this in the water soon, before the Summer is over. I could really use some help from some of you MUCH MORE EXPERIENCED BOATERS out there, and any help offered would be greatly appreciated.

Thanks So much in advance!

I'm fairly new to this Forum, as well as Outboard Repair. I bought a 1962 Starcraft a couple weeks ago, that has a 1966 18Hp Evinrude Fastwin on it. Boat had sat for 8 years prior to me getting it, and I did know enough that seals would have to be changed. Anyway, guy I bought it from had started it for me and it sounded pretty good, but once I got it home I checked Lower Unit Oil. Was None, so I filled it. Ran it for awhile in barrel and made sure water was circulating, and it was, but motor was sounding a little rough and it wouldn't shift into Forward, come to find out the forward gear and clutch were worn pretty bad, but I was able to get it redone at a machine shop, and it works well now. Also when I checked Lower Unit lube after running it, it was milky white. So I purchased a Sierra Seal kit that had absolutely no instructions with it, but the shop where I bought it said it's real easy to do(maybe if the drive-shaft O-ring weren't just about disintegrated and in the bottom of lower unit). So, I searched and searched and thought I figured out where everything went, but the O-ring that goes on the drive shaft I really wasn't sure about, and what I am assuming was the Drive-shaft O-ring that came with kit looked way to small, about a 1/4 inch in diameter,and not even a 16th of an inch thick, so I had some other Other O-rings kicking around and found one that looked about the size of the tiny piece that was left over from the disintegrated old one, and I placed it in the groove just below the spline of the top part of the drive-shaft. Also, the Spaghetti seal looked a little on the thin side, but what do I know? And the Drive-shaft seal and the Drive seal were only about half the thickness of the ones that were in there, don't know if that matters or not. Also did the water pump repair kit, minus the housing, as it didn't look that bad to me, and I just couldn't afford the $68.00 for a new one. So, after staying up all night doing this I put the finished motor back in the barrel, water seems to be circulating fine, but then I see oil quickly gathering in the barrel of water, so I shut the motor down, only to see the dreaded milky white oil-water mixture oozing from a hole on the back of the lower unit. I don't know what to do now, especially with no service manual, and I am out of money now. Is it salvageable without having to dump more money on another seal kit? Really would like to get this in the water soon, before the Summer is over. I could really use some help from some of you MUCH MORE EXPERIENCED BOATERS out there, and any help offered would be greatly appreciated.

Thanks So much in advance!