I bought an old boat to re-do last winter and have a question about the intake air path on the motor. It's a 1965 9.5 Johnson. I had the boat on the lake last weekend and the motor didn't run out 100% so right now it's on a stand and water barrel. The motor appears to be low hours and it looks like someone did some maintenance fairly recently. The spark plug wires are in great shape, plugs look good but dry like it has set for a while, and the carb & fuel pump are shiny and clean like someone rebuilt them. On the lake I thought it was running rich and was hard to start so that's why I put it on the stand. I had to change the low speed mix linkage because the way it was indexed wouldn't let it smooth out at low speeds, was too rich. It runs pretty good now except I think it's still too rich on the top end because it doesn't seem to get to the RPM I think it should. Also when I put the motor cover on it makes the problem considerably worse. The foam in the motor cover is secure and nothing seems to be restricting the air flow.

Questions:

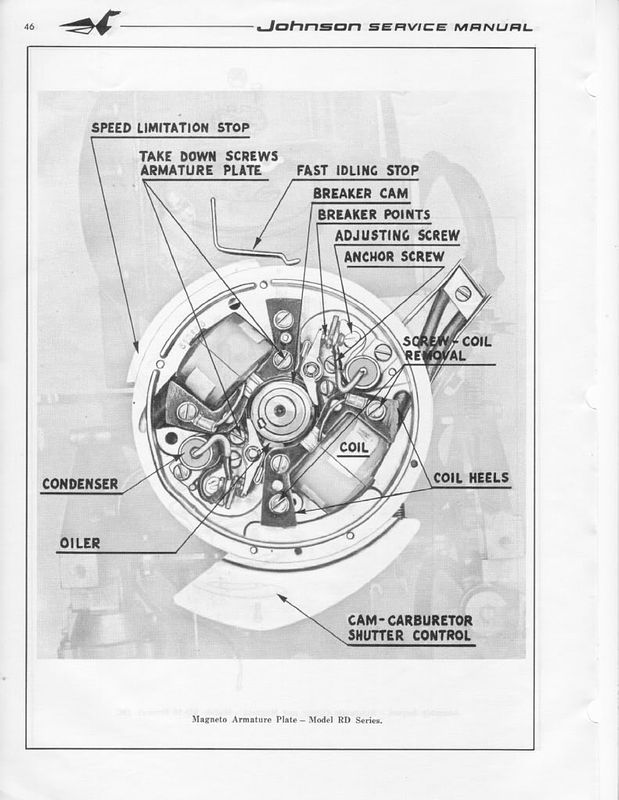

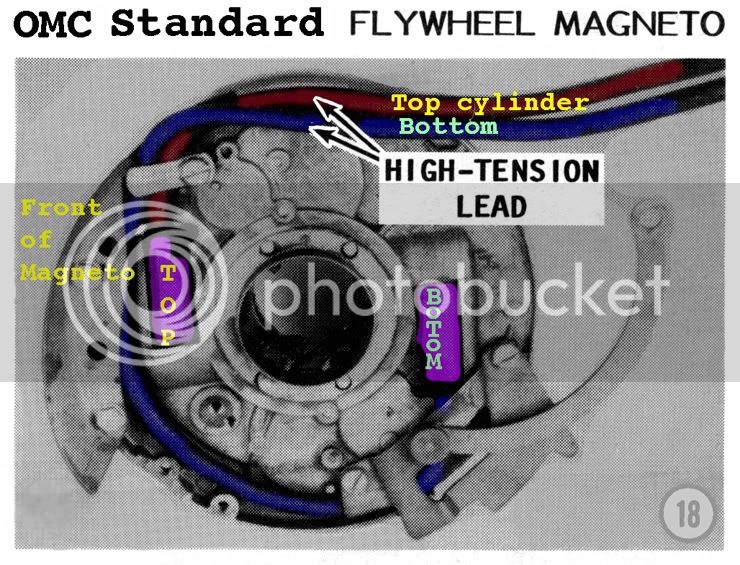

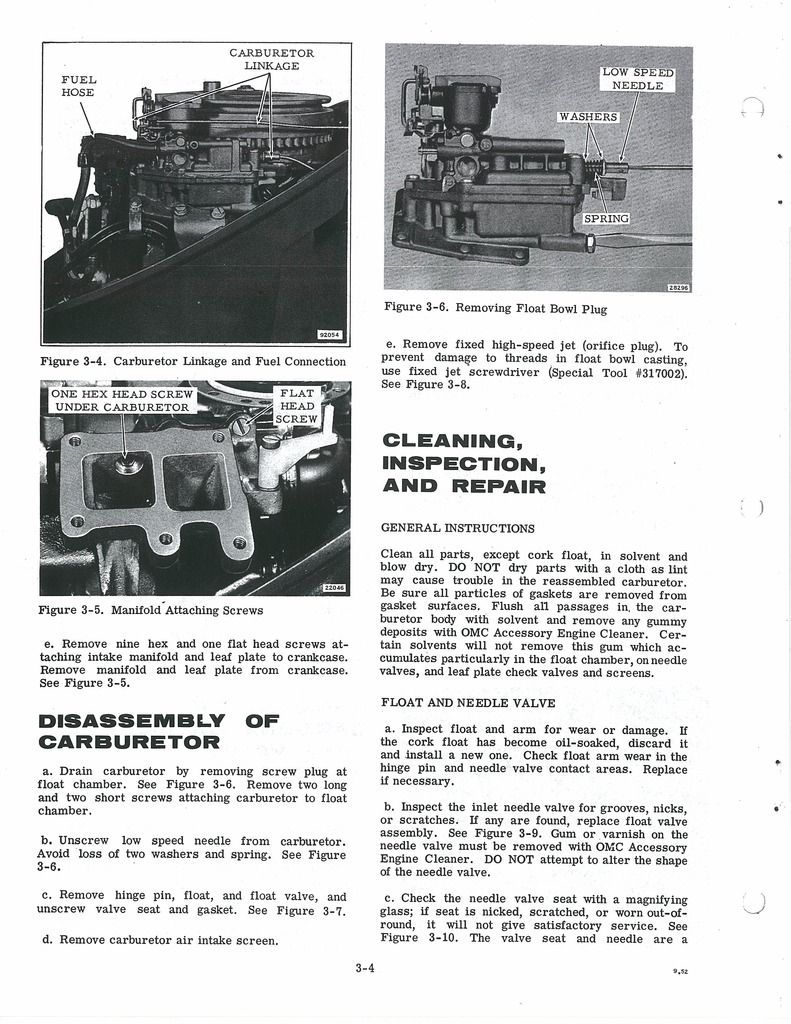

Is the combustion air drawn only from behind the front plate where the start rope, choke, and kill are mounted?

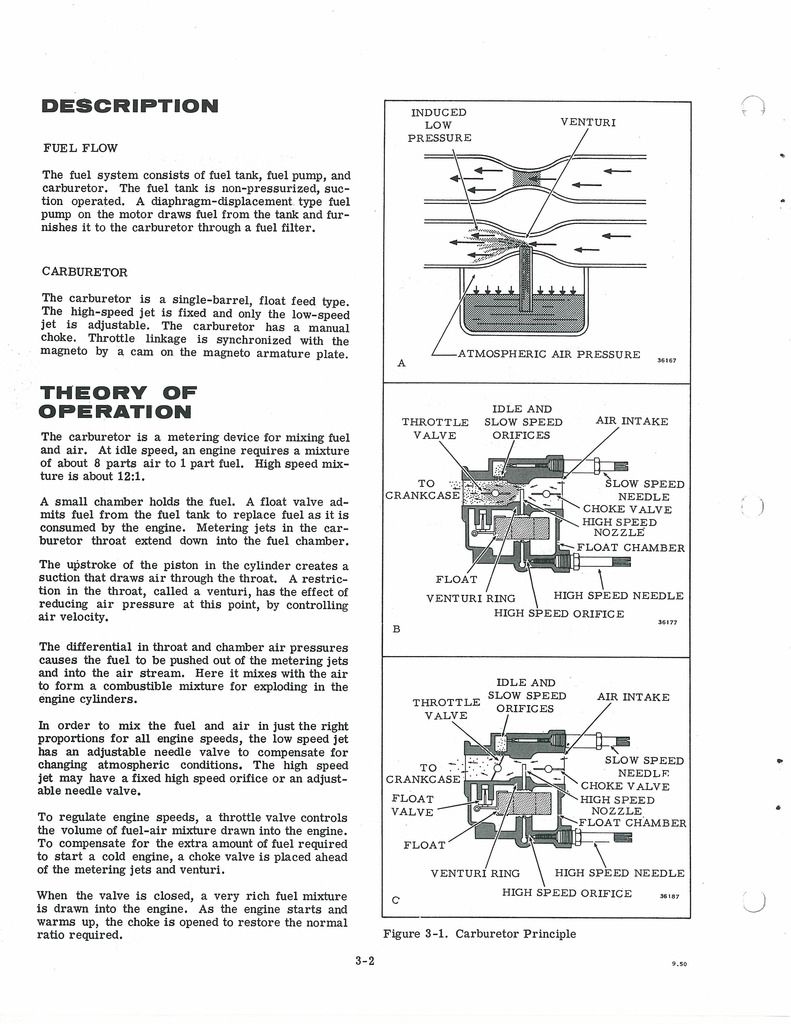

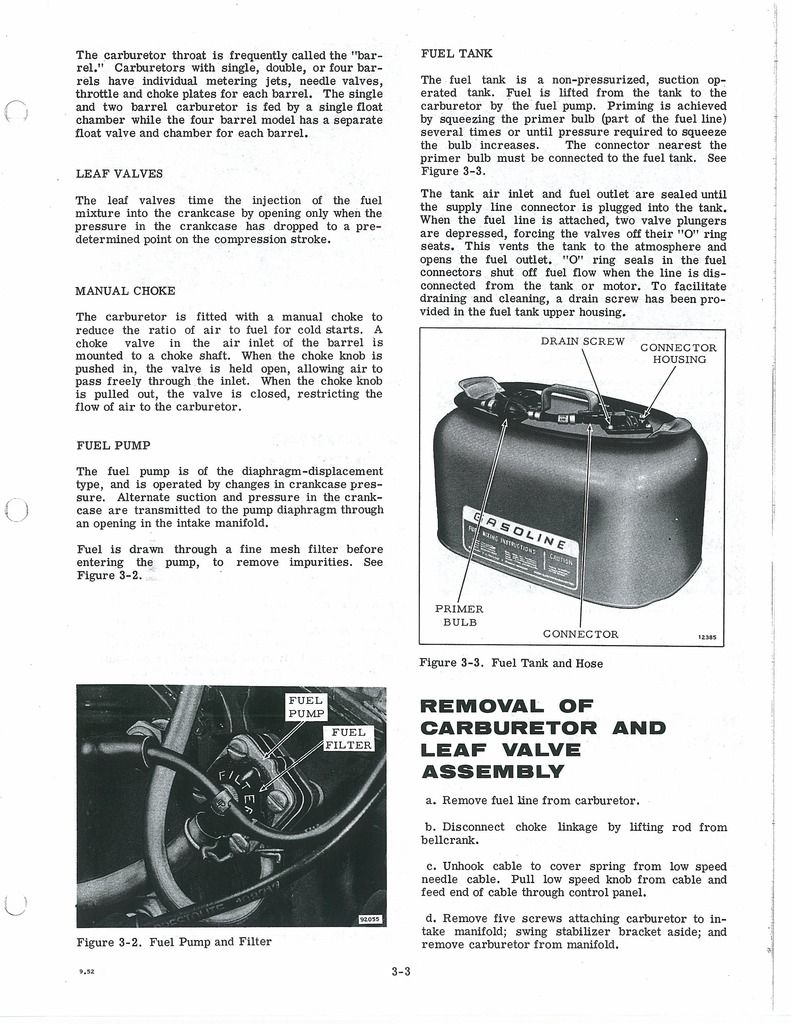

No air filter? Just the plastic screen over the top of the carb?

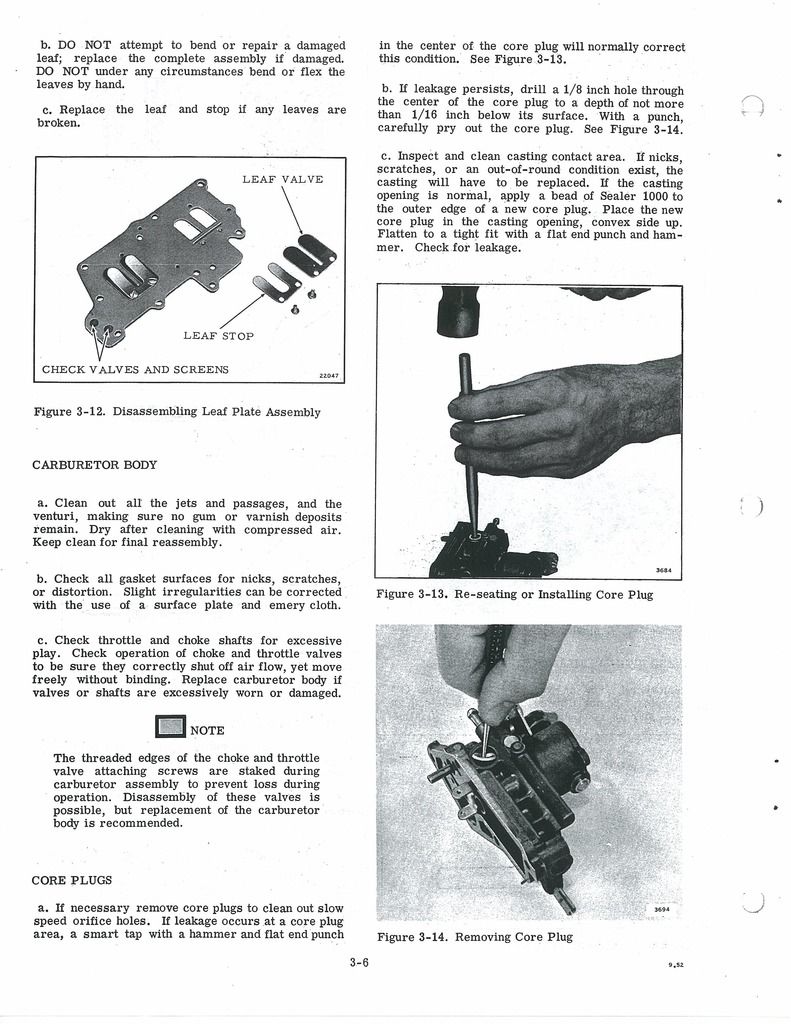

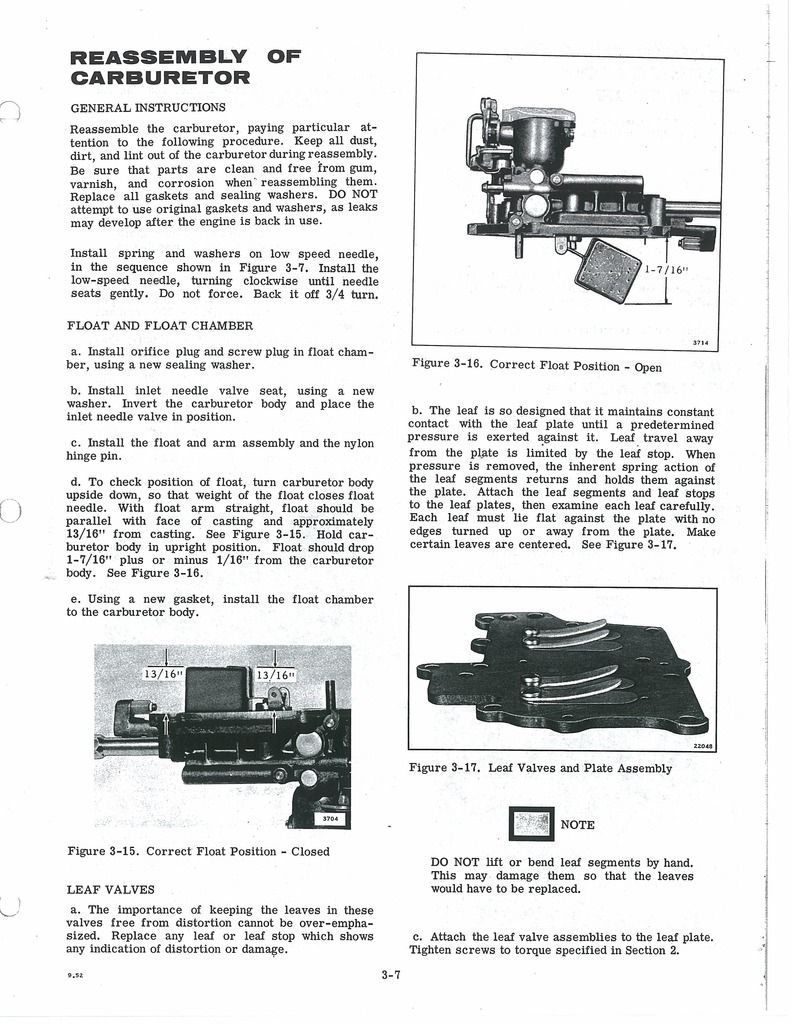

Is the top end mixture screw the little shaft and screw that runs parallel to the low end mixture screw?

Should there be a big difference in the way it preforms mid and top end when the motor cover is installed and will adjusting the jet compensate for that?

Thanks in advance for any help offered.

Questions:

Is the combustion air drawn only from behind the front plate where the start rope, choke, and kill are mounted?

No air filter? Just the plastic screen over the top of the carb?

Is the top end mixture screw the little shaft and screw that runs parallel to the low end mixture screw?

Should there be a big difference in the way it preforms mid and top end when the motor cover is installed and will adjusting the jet compensate for that?

Thanks in advance for any help offered.