Bowhunter1661

Well-known member

These are a few things I have done to improve the overall usability and reliability of my 88 Johnson 25hp.

First is an angled tach mounting bracket a guy at work made for me on a 3D printer. He custom designed the bracket for me. Before, I had the gauge mounted to the front of the cowl but I could not see the gauge while driving. The new bracket made it so the gauge is angle toward me. A lot safer peeking at it now at WOT.

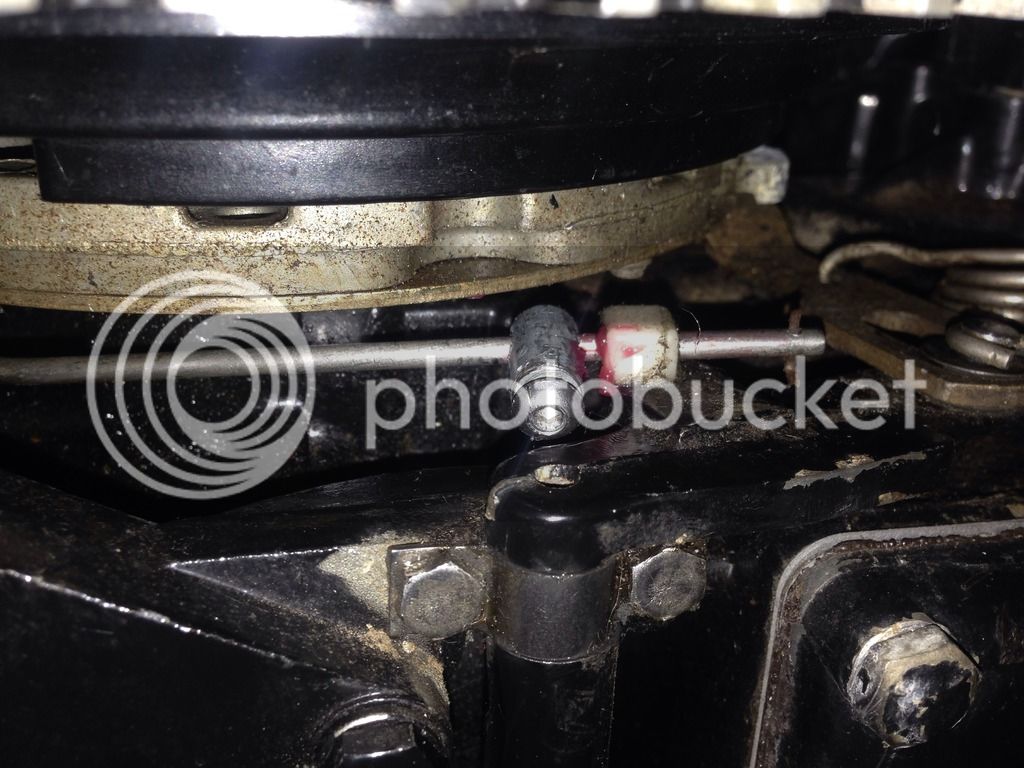

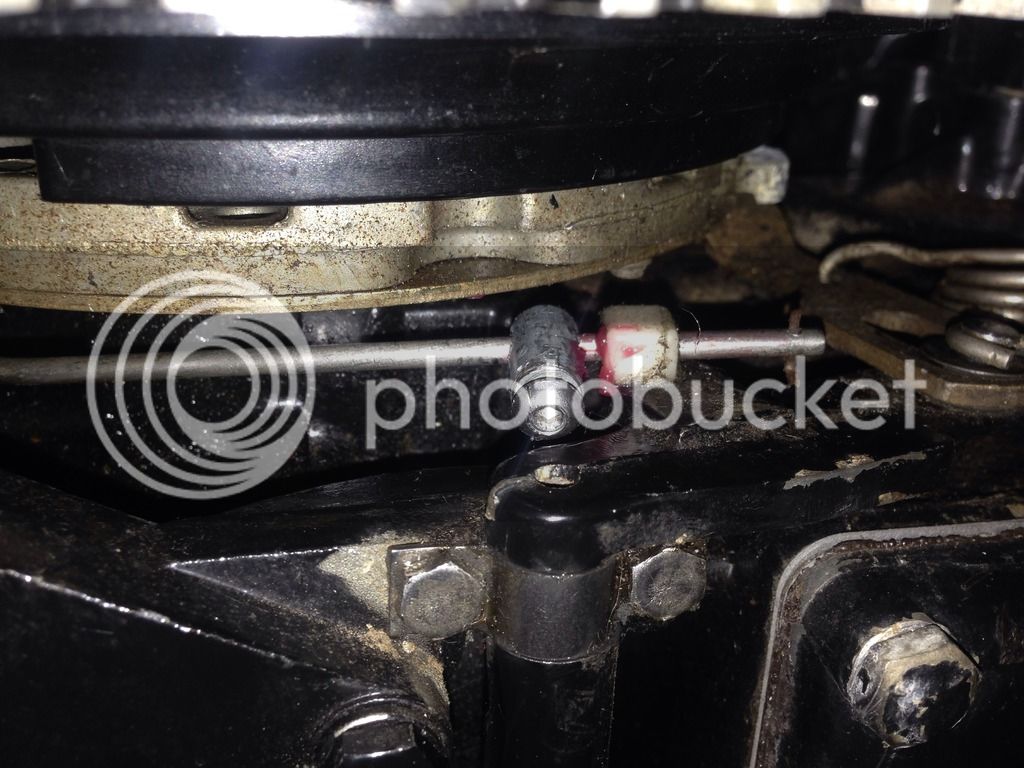

Second is the throttle linkage stop/adjuster. The oem park is made of brass with a steel flat head screw. After a few adjustments the thin brass piece broke. I bought some 1/4" bar, drilled and tapped for a 10 32 screw, then drilled the hole for the adjusting rod to slide in. It is a much more solid piece and I can tighten the screw quite snug without worrying about snapping it!

First is an angled tach mounting bracket a guy at work made for me on a 3D printer. He custom designed the bracket for me. Before, I had the gauge mounted to the front of the cowl but I could not see the gauge while driving. The new bracket made it so the gauge is angle toward me. A lot safer peeking at it now at WOT.

Second is the throttle linkage stop/adjuster. The oem park is made of brass with a steel flat head screw. After a few adjustments the thin brass piece broke. I bought some 1/4" bar, drilled and tapped for a 10 32 screw, then drilled the hole for the adjusting rod to slide in. It is a much more solid piece and I can tighten the screw quite snug without worrying about snapping it!