Ok, so I know this type of question gets asked all the time, but I have some detailed questions that I didn't find answered.

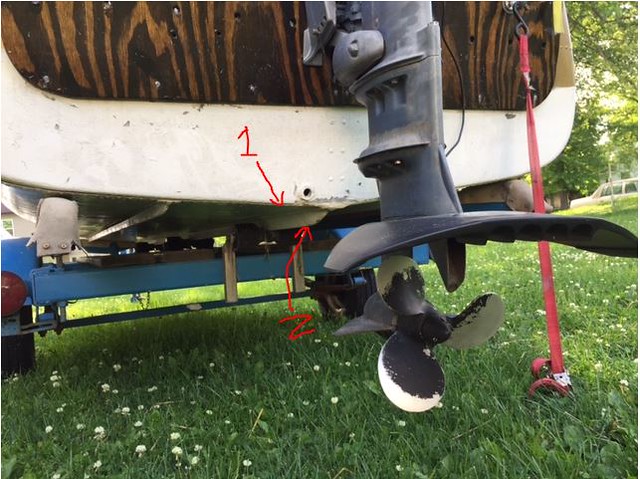

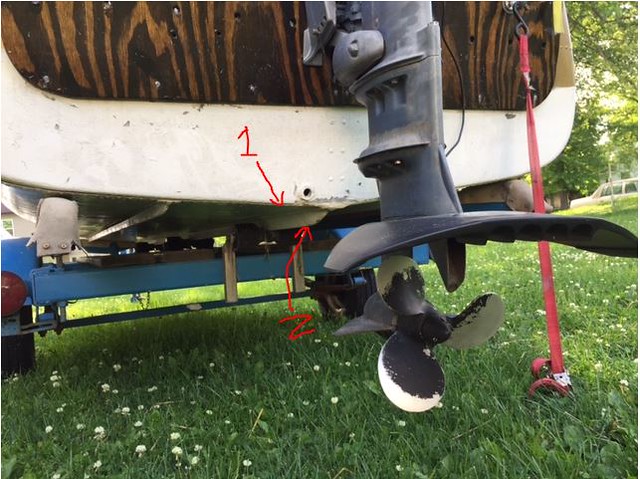

I'm trying to decide whether my motor height is acceptable. First off, does it look reasonable? I don't have any cavitation (clearly, if anything it's mounted too low).

Second, If I do want to move it, do I even have the ability to do it safely? My motor (details in sig) only has screw clamps, and from what I can tell there is no sort of adjustment on the motor to change the height it attaches to the clamp assembly. Can I just screw it on an inch higher on the transom to try it out? This seems like a bad idea to me, because then the top end of the clamp wouldn't be contacting the top (cap) of the transom.

Third, I want to compare with the common opinion of having the anti-ventilation (cav) plate 0-3" below the bottom of the hull, but when figuring this out do I measure from the bottom of the flat part of the hull as labeled #1 in the pic, or from the bottom of the center keel (I think that's the right term...) which is labeled #2 in the picture.

Maybe I'm just overthinking this, because I don't really have any performance issues, but then again, the motor has always been mounted this way so maybe I don't know what I'm missing.

1 by Photo 144, on Flickr

1 by Photo 144, on Flickr

2 by Photo 144, on Flickr

2 by Photo 144, on Flickr

I'm trying to decide whether my motor height is acceptable. First off, does it look reasonable? I don't have any cavitation (clearly, if anything it's mounted too low).

Second, If I do want to move it, do I even have the ability to do it safely? My motor (details in sig) only has screw clamps, and from what I can tell there is no sort of adjustment on the motor to change the height it attaches to the clamp assembly. Can I just screw it on an inch higher on the transom to try it out? This seems like a bad idea to me, because then the top end of the clamp wouldn't be contacting the top (cap) of the transom.

Third, I want to compare with the common opinion of having the anti-ventilation (cav) plate 0-3" below the bottom of the hull, but when figuring this out do I measure from the bottom of the flat part of the hull as labeled #1 in the pic, or from the bottom of the center keel (I think that's the right term...) which is labeled #2 in the picture.

Maybe I'm just overthinking this, because I don't really have any performance issues, but then again, the motor has always been mounted this way so maybe I don't know what I'm missing.

1 by Photo 144, on Flickr

1 by Photo 144, on Flickr 2 by Photo 144, on Flickr

2 by Photo 144, on Flickr