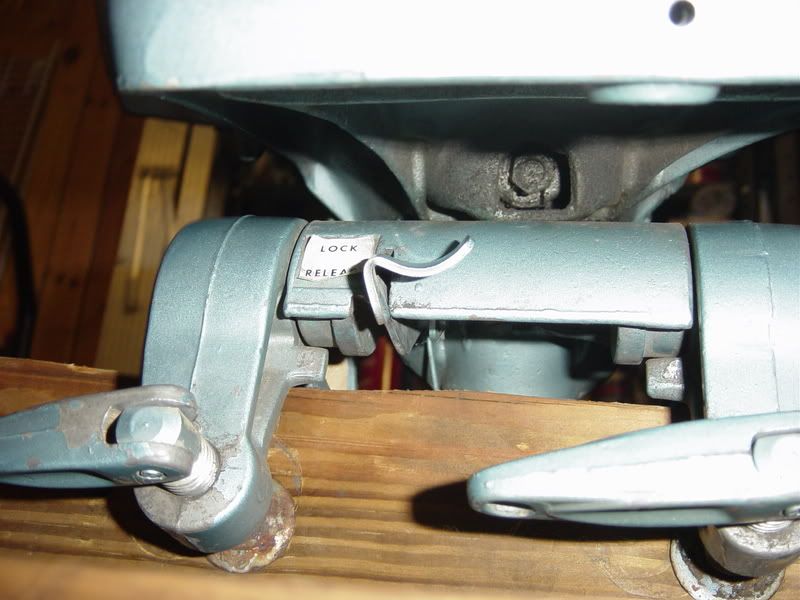

Nevermind. If yours is 5.875, the piece I have won't fit. The design you were thinking of should work. What some from that era came with from the factory was a piece of aluminum rod, bent into a square, with one side missing the middle. The two ends would bend into the top set of holes, and it would flop down when not in use, but when tilted up, the bar will tilt up, and then go into the reverse lock clip. Basically it is the same as yours, but instead of a 4 piece setup with barstock, it just uses a piece of formed rod.

As quack said, apparently while I was typing, the wood block idea works just as well. Been done for years on my Evinrude 4, but I lost my oak block, so right before vacation, I grabbed a piece of teak off the shop floor. My method of tilting the motor down involved lifting the motor up, where the block falls in. I would then tilt the motor down, and retrieve the floating block. Well, I did that on vacation, and saw the block sink straight down to the bottom of the ramp. Of course, in a vacation rental, you aren't going to find a wood scrap, so I ended up using a 4 foot long piece of driftwood off the beach (you won't find a saw in a rental either, and all the tools we brought were motor related) that was about the same width as the danged boat.