Can someone tell me what the implications of this ad are? This is the kind of motor I want for my current project.

https://minneapolis.craigslist.org/dak/boa/1918981501.html

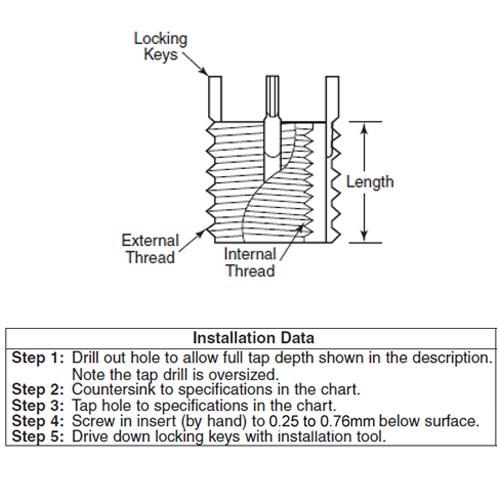

The listing is long gone. It was for a '62 Johnson ss 40hp with stripped threads. The threads turned out to be the bottom cylinder spark plug hole.

https://minneapolis.craigslist.org/dak/boa/1918981501.html

The listing is long gone. It was for a '62 Johnson ss 40hp with stripped threads. The threads turned out to be the bottom cylinder spark plug hole.