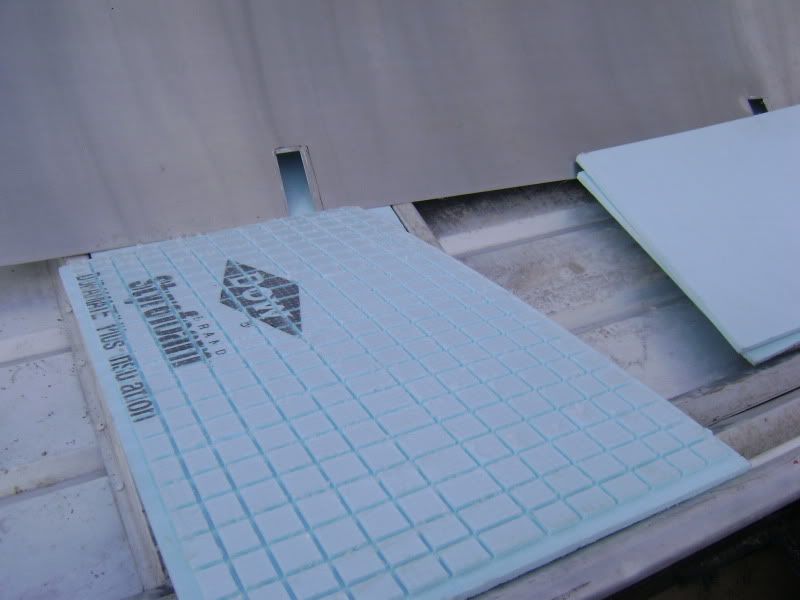

OK, it's been a while since I updated this build so I thought I'd try to get it up to date. I've been using the boat so much to go fishing with when the weather permits that I haven't gotten as far along as I'd like to but I have made progress. I read where some have concerns about how foam can trap water because of the lack of airflow. I decided to try to help that situation by cutting a checker board grove pattern in the bottom side of the bottom piece of foam for each section of the boat.

After getting all my foam installed it was time to start with the new aluminum floor to cover and hold the foam in place.

Once I had the floor in, I cut and test fitted the wood top for my rear deck.

After temporarily reinstalling the original seats, I took the boat out on a few fishing trips. After that, I decided to install the switch, wiring, and solenoid, in order to take advantage of the electric starter that the motor came with.

The next step was to fabricate some new aluminum side panels. I decided to use some tan colored textured PVC coated aluminum.

A few fishing trips later, and I decided that it was time to get the rear deck built. I decided to go smaller than my initial plans since I wanted to be able to look down into the rear floor area without having to raise any hatches. I had seen in another build thread where someone had used an aluminum ladder for their framework, and decided to copy their idea since I knew where a junk ladder was. The remainder of the frame work was done with 1"x1"x1/8" aluminum angle.

I fabricated the front wall out of the same aluminum used on the floor. I cut a hatch for the rear section and installed the cover temporarily with an old brass plated hinge I had laying around.

Current plans are to make a large fold down panel in the center of the front wall which will give me easier access to whatever is under the front portion of the rear deck. I haven't decided whether I will install a center divider wall to keep the fuel tank area separate from the front, but I definitely plan on adding a back wall.

I'm currently waiting on my new seats and hardware to arrive so I can install them. My next priority item that I want to get finished is the switch panel and wiring of the boat.