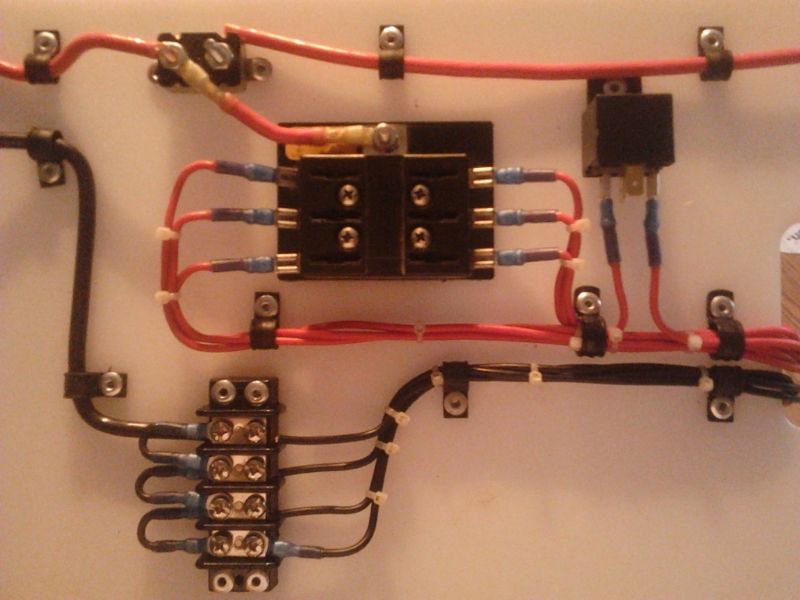

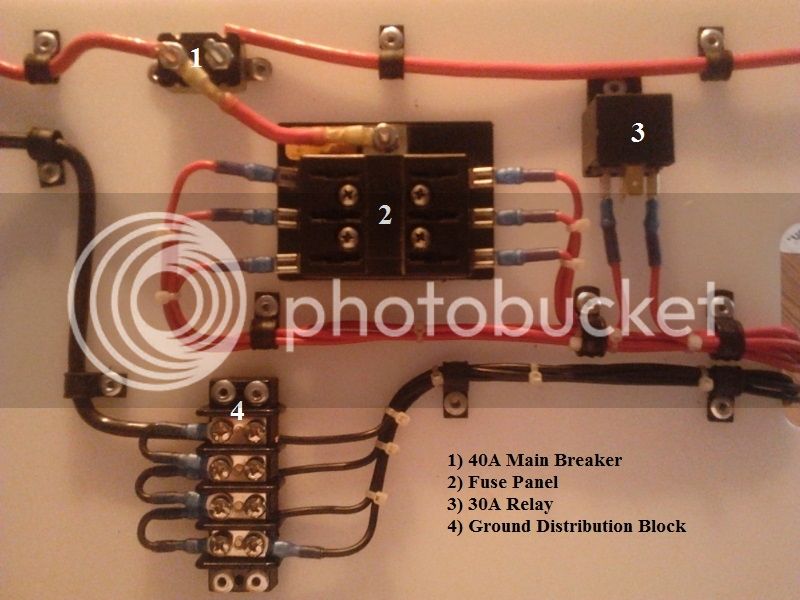

I tore my decks off, and gutted my wiring in my boat and have been fixing little things here and there, and painting the bilge area. Finally today I am seeing a little bit of forward progress. I ran out of ring connectors, but I got the rear/main distribution panel is DONE. I have 1 more smaller one to make under the console, one to make up front, and a switch panel to make, and then the wiring can be re-run and get the boat floated again!