Starkfishes

Member

- Joined

- May 28, 2017

- Messages

- 20

- Reaction score

- 0

So I've been watching is forum for quite a while and you guys have done some pretty cool projects. This weekend, I started my xPress 1652 HiD conversion. I have access to several lakes that do not allow outboards and am going to convert this rig into a bass fishing platform to rival my Ranger Z521. When complete, the boat will have a 112 Ultrex and a Lowrance HDS12.

I forgot to take a completely before picture, but here we go:

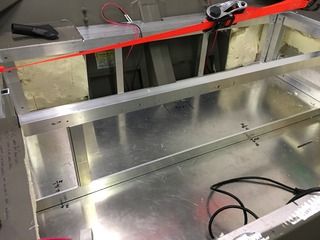

Wiring:

All of the wiring is in which includes front & rear running lights (I don't need the lights but if I ever sold the boat they would be a pain to install later), the wiring for the Lowrance, Ultrex, and the on-board charger.

Switch Panel:

The switch panel will be installed here and comes complete with push-to-reset fuses.

Rear Battery Compartment:

I removed the front cover of the battery / gas compartment of the boat to gain easier access to the space (picture of original configuration):

I am intentionally trying to make the rear end of this boat as heavy as possible as it would otherwise ride butt high once the front deck is installed. To add weight, I am using 2x12s to span the gap between the ribs and then topping that with 7/8 treated plywood. The four batteries and the on-board charger eat up most of the available space but there will be room for storage in front of the batteries for about 12-15 Plano boxes.

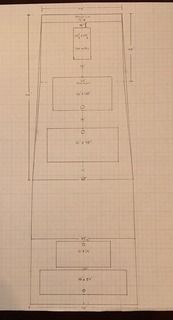

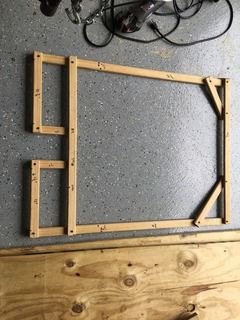

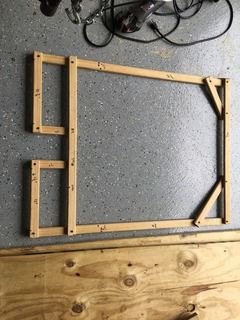

The measurements of the rear well are a little wonky and I only wanted to cut the plywood once, so I made a jig out of 1x2s for easy tracing and cutting.

What's Next:

Over the next week I will be painting the interior of the rear well flat black for a more finished look when the boat is complete. I will then add a layer of the 7/8 to the top of the rear deck for weight. I have a buddy that welds aluminum and will be taking the boat to him either late this week or early next so that we can draw up and start framing the front deck.

NELP NEEDED:

I will be having custom hatch lids made for the front and rear decks (5 lids in all). I have seen some of Dawson's from Fish-On Conversions lids on here and they look great, but take 6 weeks. Does anyone have a source for lids that can be turned-around in a couple of weeks?

I forgot to take a completely before picture, but here we go:

Wiring:

All of the wiring is in which includes front & rear running lights (I don't need the lights but if I ever sold the boat they would be a pain to install later), the wiring for the Lowrance, Ultrex, and the on-board charger.

Switch Panel:

The switch panel will be installed here and comes complete with push-to-reset fuses.

Rear Battery Compartment:

I removed the front cover of the battery / gas compartment of the boat to gain easier access to the space (picture of original configuration):

I am intentionally trying to make the rear end of this boat as heavy as possible as it would otherwise ride butt high once the front deck is installed. To add weight, I am using 2x12s to span the gap between the ribs and then topping that with 7/8 treated plywood. The four batteries and the on-board charger eat up most of the available space but there will be room for storage in front of the batteries for about 12-15 Plano boxes.

The measurements of the rear well are a little wonky and I only wanted to cut the plywood once, so I made a jig out of 1x2s for easy tracing and cutting.

What's Next:

Over the next week I will be painting the interior of the rear well flat black for a more finished look when the boat is complete. I will then add a layer of the 7/8 to the top of the rear deck for weight. I have a buddy that welds aluminum and will be taking the boat to him either late this week or early next so that we can draw up and start framing the front deck.

NELP NEEDED:

I will be having custom hatch lids made for the front and rear decks (5 lids in all). I have seen some of Dawson's from Fish-On Conversions lids on here and they look great, but take 6 weeks. Does anyone have a source for lids that can be turned-around in a couple of weeks?