12ftModder

Well-known member

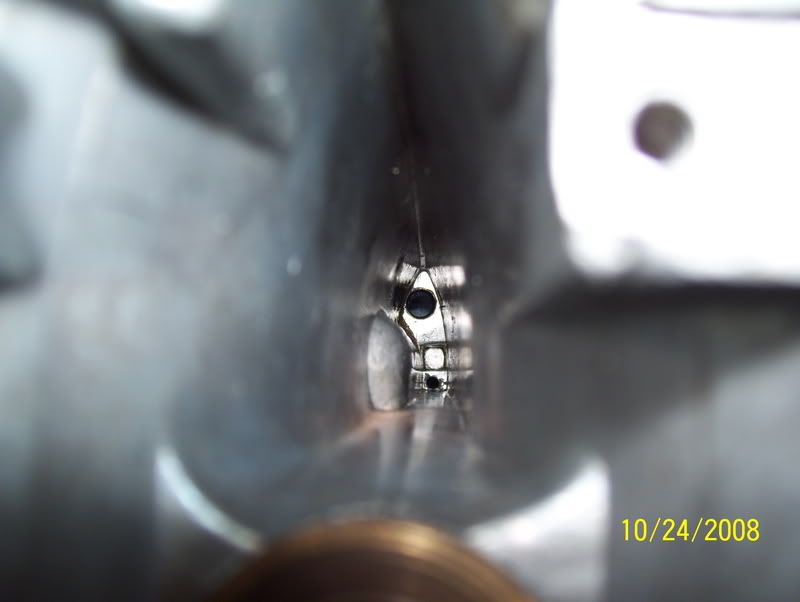

Got the top cowling ready to paint if only the wind would die down. I got my lower unit seal kit and got it the unit apart and cleaned up. Looks like I have ran into 1 problem though, the new shift rod seal (o-ring) is under a brass bushing that looks to be pressed in. And dont see how i can remove it, would like to see the tool thats used for it.

Anyway heres some more pics.

Top Cowling Ready For Paint

Lower Unit with new seal kit

My Shift Rod Seal Problem

If you have any ideas on how to do this I would like to hear them.

Thanks

Anyway heres some more pics.

Top Cowling Ready For Paint

Lower Unit with new seal kit

My Shift Rod Seal Problem

If you have any ideas on how to do this I would like to hear them.

Thanks